Vessels

ESG Cuts Steel on USACE Hopper Dredge

Eastern Shipbuilding Group, Inc. (ESG) started construction on the U.S. Army Corps of Engineers' (USACE) new medium class hopper dredge with a ceremonial steel-cutting event. "The steel cutting of this highly advanced hopper dredge marks another milestone in Eastern Shipbuilding Group’s legacy of delivering world-class vessels. We are proud to partner with the U.S. Army Corps of Engineers and Royal IHC to build a state-of-the-art dredge that will enhance our nation's waterway infrastructure,” said Joey D’Isernia, CEO of Eastern Shipbuilding Group, Inc.

“This new dredge is going to play a critical role in helping us deliver our navigation mission, which enables maritime commerce to flow on our nation’s waterways,” said USACE North Atlantic Division Regional Business Director John Primavera. “USACE hasn’t built a deep draft hopper dredge in about 45 years.”

This Hopper Dredge is being built at ESG's Allanton and Port St. Joe facilities and is scheduled for delivery in 2027, when it enters the USACE’s Ready Reserve Fleet. It will replace the 57-year-old Dredge McFARLAND based in the Corps’ Philadelphia District, one of four oceangoing hopper dredges owned and operated by USACE.

The hopper can be fully loaded with medium fine sand in less than 45 minutes, and the latest high efficiency dredge pumps, almost halves the desired discharge time. The pump maximizes the operational efficiency and durability of this hopper and is specifically developed for passage of large obstacles.

USACE's new hopper dredge will be able to load up to 15% more efficiently, reducing fuel consumption and environmental impact, thanks to the innovative ECO Control Package, which includes high-end controls for trail speed, dredge pump and draghead vizor. Unique to this hopper dredge is the use of a semi-autonomous Dredge Assist program that requires minimal human interaction to complete tasks.

The hopper dredge is equipped with a diesel-electric propulsion system that meets EPA Tier 4 and IMO Tier 3 standards. The propulsion arrangement, consisting of 3 main generators, allows for maximum flexibility, optimal fuel consumption and operational safety in case of engine failure.

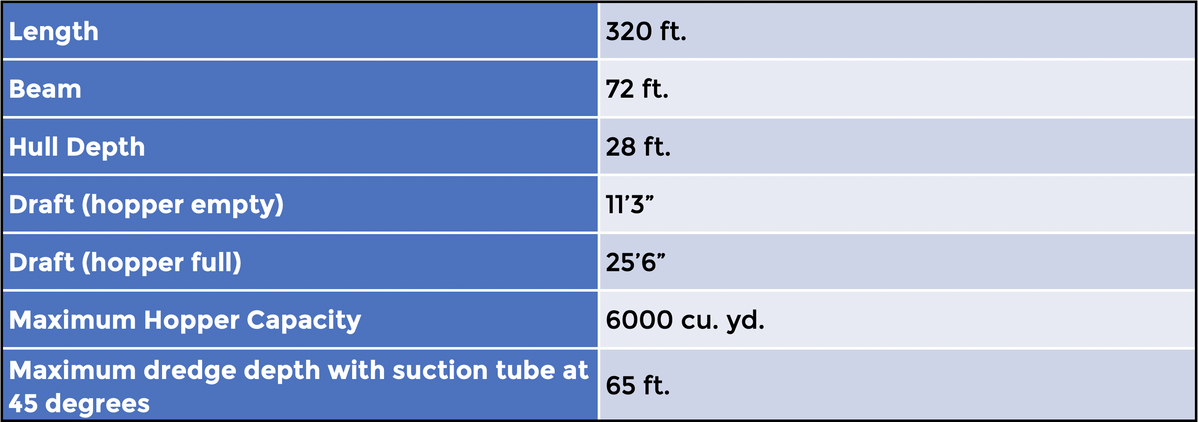

Vessel Specifications:

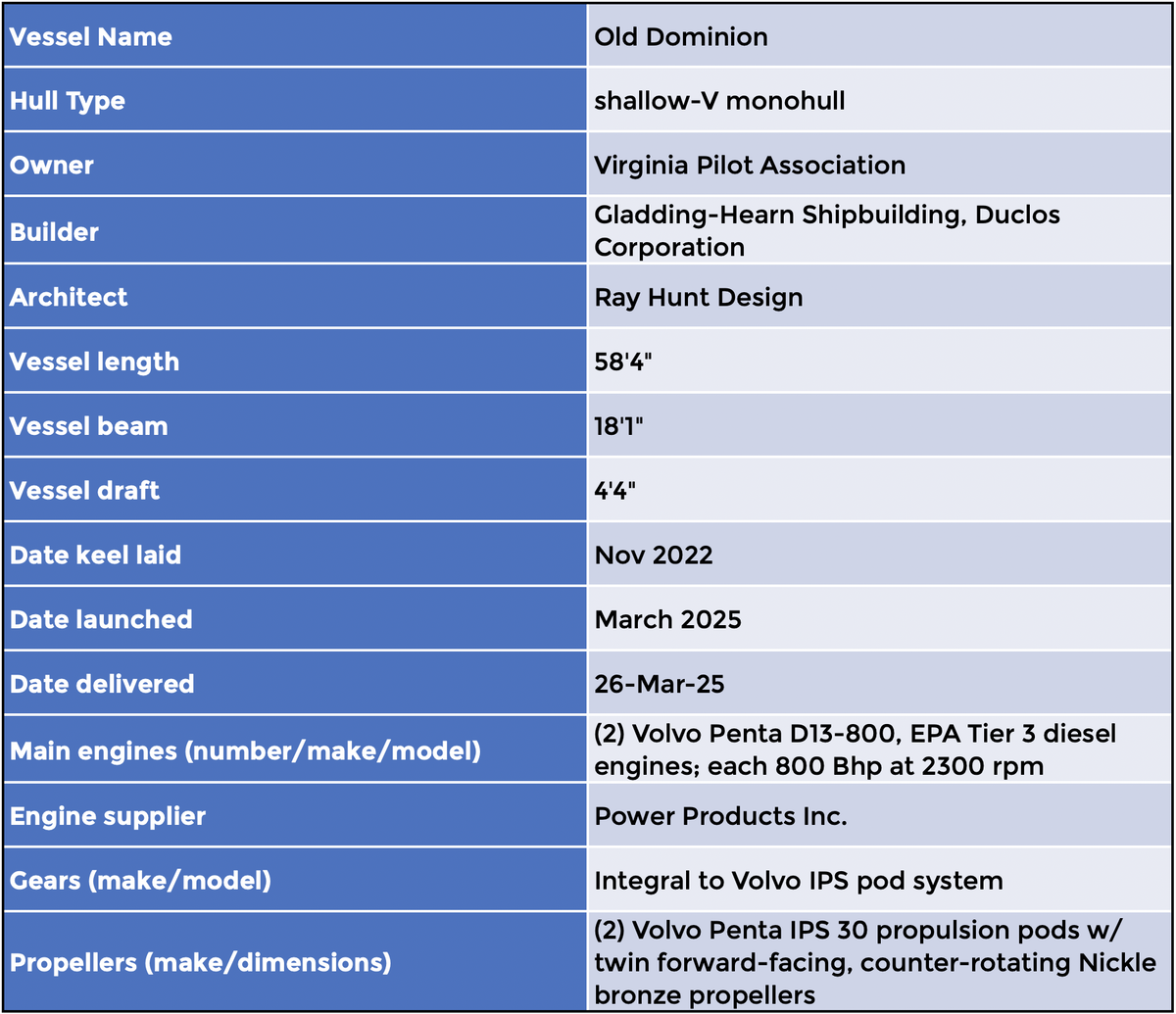

Virginia Pilots Order Harbor Launch from Gladding-Hearn

The Virginia Pilot Association has taken delivery of a new high-speed, pilot boat from Gladding-Hearn Shipbuilding, Duclos Corporation. It’s the Virginia pilots’ tenth launch built by the Somerset, Mass., shipyard since 1983.

The all-aluminum launch is designed and outfitted for the Pilot’s Hampton Roads harbor station. An all-new, shallow-V hull by Ray Hunt Design was created to optimize speed with a low wake while maintaining excellent seakeeping and boarding performance. It displaces about 2,000 pounds less than a similar sized offshore pilot boat. As a result, the boat accelerates faster and reaches a higher top speed, explained Peter Duclos, the shipyard’s co-president and director of sales.

The pilot boat measures 58 ft. overall, with an 18-ft. beam and a 4-ft. draft. Powered by twin Volvo Penta D13-800, EPA Tier 3-certified diesel engines, each producing 800 Bhp at 2300 rpm, the vessel’s top speed is over 36 knots.

Each engine is connected to a Volvo Penta IPS 30 propulsion pod, fitted with dual forward-facing, counter-rotating propellers and integrated exhaust system, and Volvo Penta’s EVC integrated electronic steering and control system at the helm station and aft docking station. A Humphree interceptor trim control system with its Automatic Trim Optimization, Automatic List Control, and Coordinated Turn Control functions has been installed at the transom. An Alaska Diesel generator, with 12kW of output, provides electricity.

The vessel’s pilothouse is placed amidships on a flush deck, with the helm station on center. A lightweight canopy extends approximately seven feet aft of the pilothouse to accommodate small groups. The arrangement is designed for up to two crew to stay overnight or live aboard. The pilothouse is outfitted with four Norsap shock-mitigating reclining seats, a small galley and settee with a table. The forecastle includes an enclosed head, two berths, a hanging locker and exposure suit cubbies.

Vessel Data and Specifications Information

TSH Dredge Adele

Eastern Shipbuilding Group, Inc (ESG) is announced The Dutra Group has issued a Notice to Proceed for the new-build construction of a 10,464 cubic yard Trailing Suction Hopper Dredge, the Adele, to be built at ESG's Allanton and Port St. Joe facilities. Delivery is scheduled for late 2028. Adele will join The Dutra Group’s 9,870 cubic yard Trailing Suction Hopper Dredge Stuyvesant. The new vessel’s name honors Bill Dutra’s mother, Adele Coelho. She was born on December 4, 1924 in Honolulu, Hawaii. Raised on the island of Molokai, she subsequently worked as a receptionist to the US Army Corp of Engineers at Pearl Harbor where she met Bill’s father Edward, who was then a captain in the U.S. civilian dredging fleet under the Jones Act.

Adele is based on Royal IHC’s Beagle design. The IHC Beagle Mk2 is a twin screw trailing suction hopper dredge with a maximum hopper capacity of 10,464 cu. yd. The hopper has a V-shaped cross section and is provided with a single row of bottom doors, which is ideal for quick offloading of dredged material. The design also incorporates a bow connection for high efficiency material pump off to service the shoreline and wetland material placement market. The hull shape is optimized with a bulbous bow to reduce drag and improve fuel efficiency.

Shipbuilding RFP Issued Hydrogen-Hybrid RV

UC San Diego’s Scripps Institution of Oceanography issued a request for proposals (RFP) to select a shipyard for the final design and construction of its new 163-ft. Coastal Class Research Vessel (CCRV). The vessel will feature a dual-powered hydrogen fuel cell and diesel-electric propulsion system, capable of conducting 75% of its missions using only liquid hydrogen. When running on hydrogen, CCRV will produce zero emissions and operate with minimal noise, ensuring contamination-free sampling and enhanced performance of its underwater acoustic sensors. Shipyards interested in submitting proposals can contact Lynda Ta at L2ta@ucsd.edu or Gary Oshima at gmoshima@ucsd.edu. Proposals will be accepted through May 9, 2025, with a final selection expected by June 20, 2025.

Tidewater Order Liquid Refined Product Barges

Tidewater Transportation and Terminals announced the finalization of a contract with Gunderson Marine and Iron, Portland, Oregon, for the construction of four new liquid refined product barges. The barges will measure 272 x 42 ft., and 18.5-ft. deep, with a capacity of 20,000 barrels. Designed and constructed for service on the Columbia Snake River System, these inland liquid tank barges will be certified by the United States Coast Guard and comply with OPA 90 requirements. The first two barges are scheduled for delivery in May and July 2026, with the remaining two arriving in November 2026 and February 2027.