Vessels

New Concepts, Designs & Deliveries

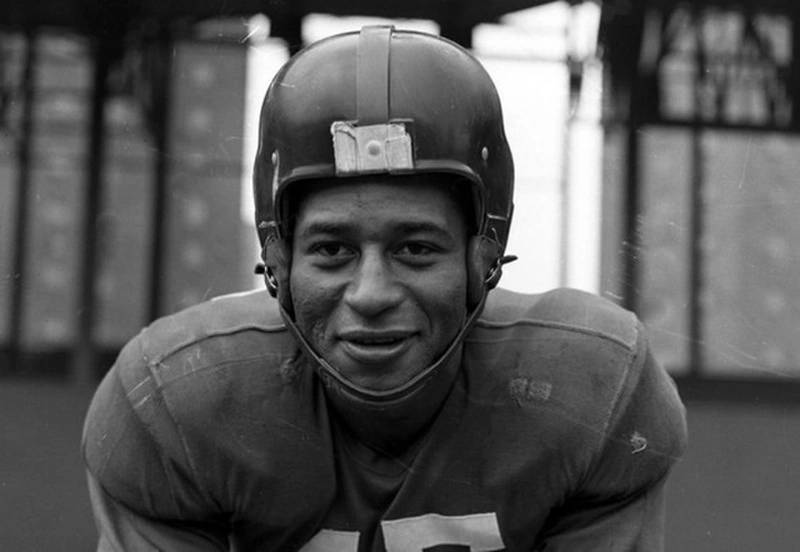

USCG FRC Honors Emlen Tunnell, Coast Guard Hero, NFL Great

USCGC Emlen Tunnell in Key West, Florida.

Emlen Tunnell, the first African American to play NFL football for the New York Giants, also posthumously received the Coast Guard Silver Lifesaving Medal for his actions in World War II.

Bollinger Shipyards delivered the Fast Response Cutter (FRC) USCGC Emlen Tunnell to the U.S. Coast Guard in Key West, FL. Named to honor Coast Guard hero and NFL great Emlen Tunnell, the cutter is the fourth of six FRCs to be home-ported in Manama, Bahrain, which will replace a 110-ft. Island Class Patrol Boats. The USCG ships are stationed in Bahrain supporting the Patrol Forces Southwest Asia (PATFORSWA).

Tunnell was instrumental in saving the lives of two shipmates in two different heroic actions, and also as a ground-breaking African American in the world of professional sports. Tunnell played college football at Toledo before and after World War II — he enlisted from 1943 to 1946 — and continued his collegiate career at the University of Iowa. After leaving college in 1948, he hitchhiked from his home in Pennsylvania to New York for a tryout with the New York Giants, and Tunnell was the first Black player signed by the Giants and later played for the Green Bay Packers. He ended up playing 14 seasons in the NFL and when he retired as a player, he held league records with 1,282 interception return yards, 258 punt returns, 2,209 punt return yards, and 79 interceptions – the second most interceptions in NFL history today. In 1967, Tunnell was the first Black man and the first defensive specialist to be enshrined in the NFL Hall-of-Fame in Canton, Ohio.

FRCs have conducted operations as far as the Marshall Islands—a 4,400 nautical mile trip from their homeport. Measuring in at 154-feet, FRCs have a flank speed of 28 knots, state of the art C4ISR suite (Command, Control, Communications, Computers, Intelligence, Surveillance, and Reconnaissance), and stern launch and recovery ramp for a 26-ft., over-the-horizon interceptor cutter boat.

Fincantieri to Support Daewoo in Aircraft Carrier Design

Fincantieri signed a contract with Daewoo Shipbuilding & Marine Engineering (DSME) to support the Conceptual Design of the new class of aircraft carriers “CVX” for the Navy of the Republic of Korea (South Korea), with basic design starting later this yar.

The signing took place between Jung Woo Sung, Vice President Naval & Special Ship Marketing Division of DSME, and Marco Cerruti, Regional Sales Manager of Fincantieri, in the presence of Federico Failla, Italian Ambassador in Seoul, Vice Admiral Dario Giacomin, Deputy Defense General Secretary – Deputy National Armament Director, and Rear Admiral Antonio Natale, Advisor of the Chief of Staff of the Italian Navy.

Fincantieri will advise DSME based on the expertise gained with the construction of the LHD (Landing Helicopter Dock) Trieste, which will be delivered next year to the Italian Navy. Fincantieri already has a strong relationship with the South Korean Navy, and in fact, through its subsidiary Seastema, the Group is cooperating in the construction of eight new Daegu class frigates (FFX-II) for the national Navy, providing SEASNavy, an innovative integrated platform management system (IPMS).

A “Swiss Army knife” that fits in a Mooring Pocket

Moduteh Marine, of Tacoma, Wash., completed a contract to build a fleet of five small tugs that carry the military designation Work Boat Docking. “The mission of the CNIC Work Boat Docking (WB Docking) is to provide waterborne support at U.S. Navy Installations,” said Modutech’s Brian Swindahl. “The boats are required to have the ability to safely assist vessels including submarines for mooring and dry-docking, open and close security barriers, as well as to tow/push floating port operations support equipment. The boats must include propulsion equipment that is optimized for bollard pull, be highly maneuverable, and include sufficient deck fittings and winches to tow astern, alongside, or push.”

In effect, the Navy wanted a Swiss Army knife that would fit in a mooring pocket. Modutech built a series of five boats that do just that. The rectangular shaped 25- by 14-ft. hulls have an 8-ft. draft. The relatively deep draft results from the requirement that these little boats be highly maneuverable. To meet that requirement, they are fitted with a single Schottel SRP 150 azimuthing drive. The drive has a 41.3-inch propeller in a nozzle. The forward-mounted drive is protected by a heavy pipe guard. A pair of fins, with approximately the same depth as the single drive, enhance the maneuverability while providing tracking stability.

The powerful heart of these remarkable craft is a single Cummins QSM11 engine, producing 450 hp at 2,100 rpm. This big power gives the little tug a speed over 7.5 knots and a bollard-pull in excess of 10,000 pounds. This power allows the tug to operate in both push and towing methods as required.

The steel hull carries an aluminum pilot house with heating and air conditioning. The wheelhouse can be removed for repair or transportation. Similarly, a pair of push knees mounted forward are removable. Arching from the top of the push knees, over the house, and down to the aft deck, a cage allows the boat to pass easily under mooring lines. Normal operation will be with a two-person crew, although there is room for an additional five passengers. The five Yard Tugs were deployed to naval yards in 2020.

Keel Laid for Combat Support Ship at Damen Galati

Last month Damen Shipyards Galati performed the keel-laying ceremony on the Combat Support Ship (CSS) Den Helder for the Royal Netherlands Navy. The keel laying ceremony was performed by the Director Defense Material Organization (DMO), vice admiral Arie Jan de Waard and vice admiral Rob Kramer, Commander Royal Netherlands Navy (RNLN).

The yard carried out the steel cutting in December 2020, and today all of the building blocks for the actual construction of the ship in Romania are ready. The engineering of the CSS has been largely carried out in the Netherlands. Damen Naval division director Hein van Ameijden said “More than a year after signing the contract for this ship, Damen Naval has concluded 116 purchase contracts, of which 82 are with Dutch suppliers. These are with companies coming mostly from the Rijnmond and Zeeland areas.”

In the past for the keel laying. a coin was placed under the wooden mast for prosperity. Nowadays, with the ships made of steel, the coin is placed under the keel block. Both admirals performed this operation for the CSS, placing a coin from 1822 for the occasion. This was an important year for the RNLN, in which, after various plans and initiatives for fort building in the Napoleonic era, the marine establishment with drydock in Den Helder was transferred to their ownership.

The ship is scheduled for completion in 2023, and after commissioning, testing and shipyard trials the ship will sail to Den Helder, where the accessories and the combat management system will be installed before the ship is transferred to the navy in 2025.

The 180-m long ship was designed in close collaboration with the DMO and the RNLN. It is based on the Joint Support Ship HNLMS Karel Doorman, previously built by Damen. When in service it will have a 75-person standard crew with the option to carry an additional 85 people on board. In addition to space for fuel and munition to supply other ships, there is room for several helicopters and 20 containers.

BMT to Design Boats for UK Ministry of Defense Police (MDP)

BMT and Marine Specialized Technology (MST) have partnered and been selected by the UK Ministry of Defense Police (MDP) to provide 18 high-speed patrol vessels. The BMT design is 15-m long, powered by twin inboard diesel propulsion engines driving twin waterjets. Designed to reduce fuel consumption, the boats will be capable of 30 knots and will be operated by the UK MDP. The bridge will feature a fully integrated C4ISR and craft management system, using the latest open-architecture structure and shock mitigation crew seating.

BMT will provide an Integrated Logistics Support (ILS) package.

New RAmparts 3200-SD Tug for the Royal Thai Navy

Robert Allan Ltd. signed a contract with Asian Marine Services Public Company Limited (ASIMAR) of Thailand for the design of a RAmparts 3200-SD tugboat for the Royal Thai Navy.

RAmparts tugs are a proven series of Z-drive tug designs with more than 180 RAmparts 3200 tugs having been built to date. The Royal Thai Navy currently operates two RAmparts 3200 tugs, and this third vessel will, similar to the previous two tugs, have approximately 55 Tons Bollard Pull and a speed of more than 12 knots. This tugboat will support fire-fighting missions with a 2,400 cu. m./hr. Fi-Fi pump with fire monitors capable of 120m throw distance and oil spill recovery missions can be accomplished with DESMI oil spill response solutions and environmental friendly, biological formular oil dispersant bioQ.