Ecochlor’s Reliable Filterless BWMS Fills Marketplace Void for Shipowners

By Panos Smyroglou, VP Sales & Marketing

Let’s be honest, the reason most ballast water management systems (BWMSs) use filters is that the majority of BWMS treatment technologies cannot work effectively and are unreliable without one and, truthfully . . . if they could treat ballast water without a filter, then they would!

Shipowners want BWMSs that don’t include filters because by eliminating the filter you have less issues during ballasting operations, save money, need less power, require less maintenance and it is simpler for crew to run.

To expand on that concept, filters have well-known issues in turbid or high-sediment water, often clogging and requiring extended back flush cycles or maintenance which can reduce the ballast rate or stop the ballasting operation altogether. Plus, there are the additional costs in the installation for piping and equipment.

So why have a filter? Good question! In support of filters, the main argument I have heard is that they prevent sediment going into ballast tank, which then requires additional cleaning. However, what they don’t tell you is that most BWMSs use filter meshes of around 40 microns and since much of the sediment material found in ships’ ballast tanks are fine-grained particles under 35 microns then a filter-in BWMS does not have as large an impact upon sediment build-up as you might think.

Additionally, the need for filters using UV treatment is obvious since the UV light must reach and disinfect organisms that might otherwise get shielded behind silts or sediments in ‘dirty’ water.

Likewise, an electro-chlorination (EC) or sodium hypochlorite-based treatment technology doesn’t function optimally as a filterless system because you would absolutely have to significantly increase the chemical dose. This is because EC treatments react with any organic matter, living or dead – so in waters with high levels of total suspended solids, the sodium hypochlorite reacts with everything, requiring a considerable increase in the dose or else it runs the risk of insufficient biocide left over to kill the living organisms. Certain EC-based BWMS manufacturers openly admit this issue, however, equally there are others that disregard this to the detriment and uncontrolled risk of their own clients.

The Ecochlor® BWMS treatment technology does not suffer any such issues. This is because chlorine dioxide (ClO2) is selective in its reactions – in other words it reacts primarily with living organisms, rather than all organic matter. Due to this limited reaction with non-living organisms, the need to increase the dose to effectively treat the ballast water is minimal. Thus, making the Ecochlor system a particularly ideal and safe option for filterless ballast water treatment applications.

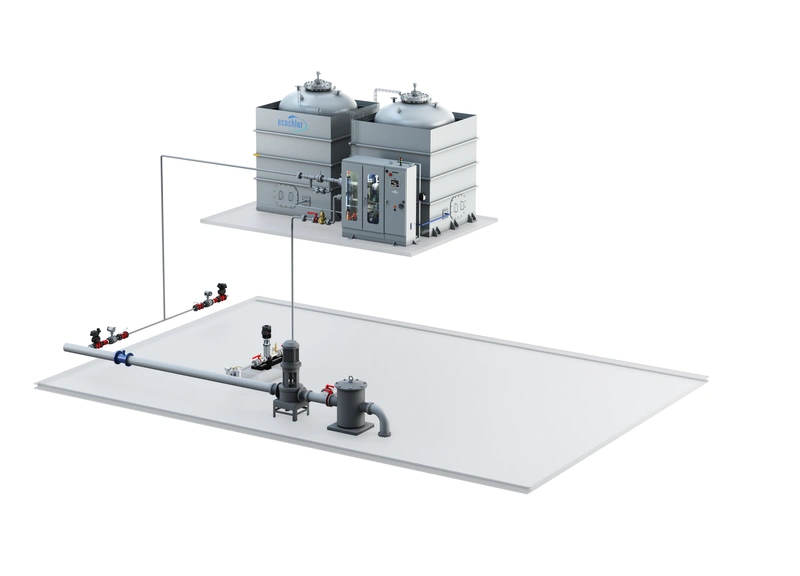

In 2021, Ecochlor launched the EcoOne® filterless BWMS. This system treats ballast water by injecting a small dose of 4.6 mg/L of chlorine dioxide ClO2). Vessels operating this system can operate anywhere in marine and brackish waters (i.e., ≥ 1PSU) and with no restrictions on temperature or turbidity. The dose rate of 4.6mg/L compares very closely with the dose rate of 4.2mg/L which we use for our filter-in systems.

If a vessel has to regularly ballast in waters below 1 PSU, then Ecochlor offers a hybrid version of the EcoOne®. This system gives shipowners the ability to operate either with or without a filter and is great for shipowners who want the flexibility of unrestricted operation globally along with the convenience of having a filterless system when they want it. Additionally, some owners have expressed a desire to have a different capacity flow rate on freshwater compared to marine and brackish. This would allow them to fit a smaller capacity filter for the normally few freshwater operations only and, thereby, still enjoy the benefits of a smaller footprint for the filter.

The EcoOne® BWMS has the same design and benefits as a standard Ecochlor® BWMS with a few limited modifications. Of course, this includes the removal of the filter but the only equipment additions are: a duplex strainer; a conductivity sensor to certify that the unit is being operated in the correct mode for either freshwater or marine/brackish water; a pressure transmitter to further enhance the reliability of the operation; and lastly, some updated software. As you can see from the minor equipment changes, upgrading a standard Ecochlor® two-step filtered system to an one-step EcoOne® BWMS is a fairly simple procedure.

There are a number of really beneficial features of EcoOne® BWMS for the ship’s crew ─ even easier operation and maintenance along with very low power requirements. Additionally, since the system doesn’t require re-treatment or neutralization on discharge and doesn’t have a filter, you can gravity ballast both on intake and discharge and the latter directly out of the ballast tanks, which is a very valuable feature in the case of Top Side Tanks on a bulk carrier.

For the shipowner, there are also some nice environmental advantages of the EcoOne® BWMS. It has extremely low energy requirements, thus reducing the ship’s carbon footprint. For example, once you take out the filter, for a ship with ballast flow rates between 500–3000 m3/hour the power requirements would range from an astonishing 5 to 7 kW; with flow rates between 3,000–10,000 m3/hour the power requirements range from 10 to 15 kW.

Additionally, ships will soon be required to use shore-to-ship power to reduce greenhouse gas emissions, otherwise known as cold ironing. It would make sense for shipowners to install BWMS equipment with the lowest possible power rating since ballasting operations are handled in port. The EcoOne®, with its very, very low energy usage would be a clear choice in helping shipowners lessen these power costs!

Operating a filterless BWMS offers huge benefits to the shipowner in terms of OPEX and CAPEX costs as well as for the crew through the simplicity of operating the system along with less maintenance requirements. Long-term though, a reliable, efficacy-strong, filterless technology will allow charterers and owners to achieve their environmental and compliance responsibilities throughout the lifetime of their vessels.