SMM 2024

New Technology

SMM 2024 New Tech Review

Last month in Hamburg, Germany at SMM 2024 – the world’s largest and best exhibition centered on shipbuilding and ship machinery – companies used the platform to launch a dizzying array of new product and technology. If you missed the event, find here the ‘editor’s choice’ of the best new tech showcased in Hamburg.

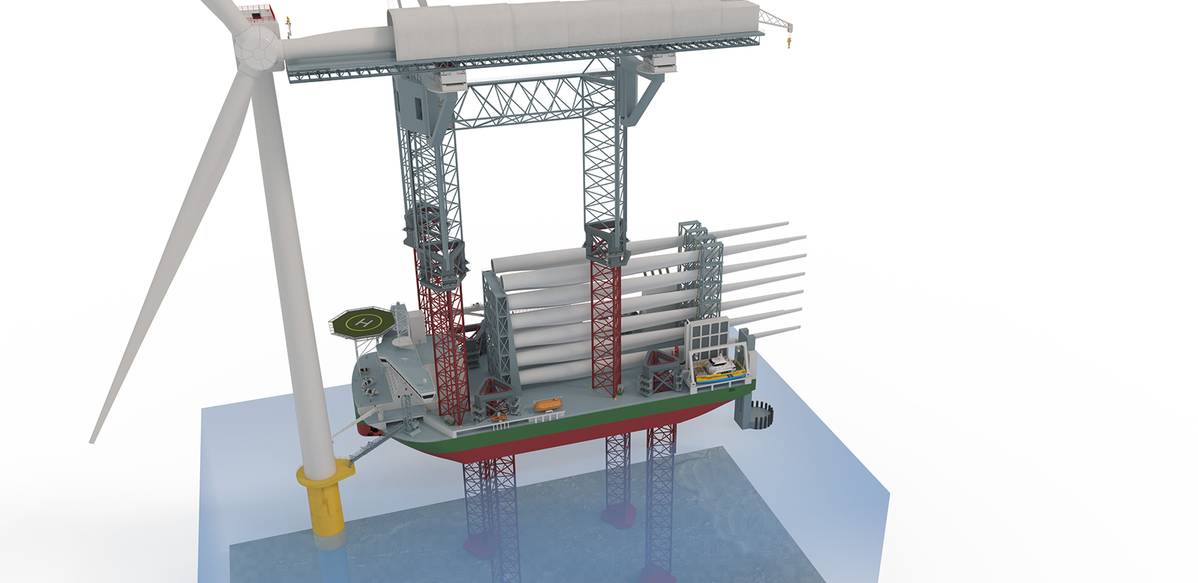

Jack-Up Platform Enables All-Weather Nacelle Maintenance

Knud E Hansen designed a “Jack-up on Jack-up” vessel concept for offshore wind farm maintenance.

The four-legged jack-up vessel features a 15m wide working platform that can be jacked-up to the height of a nacelle to provide a safe platform for maintenance work on the blades eliminating the need for hazardous rope access.

With a telescopic weather cover fitted on the platform, work on the blades can be done in practically all weather conditions, day or night, resulting in more working hours annually than with conventional maintenance vessels.

A large, air-conditioned workshop is located at the aft end of the work platform, and when the weather cover is deployed, a virtual factory hall is created around the blade, allowing all types of work to be performed on the blade, minimizing the need to remove the blades and transport them to shore for repair.

Additionally, there is the possibility of inserting an X-Y motion compensating system between the work platform and the platform carriers so the “factory hall” can remain geostationary.

A “cherry picker” mounted on a hammer head at the platform’s opposite end provides the access to the nacelle. The main crane is fitted on the elevating structure, allowing for the use of a conventional pedestal-mounted crane with a boom that is approximately 30% shorter than that of a conventional wind turbine maintenance vessel, which should be able to reach the same height, providing a much better view of the blades and the nacelle from the crane driver’s cabin.

Measuring 154m in length and 64.4 m in breadth, the vessel is designed for all kinds of maintenance work on wind turbines up to 20MW, including replacement and handling of nacelles weighing as much as 1,000t at a hub height of 175m, and managing blades up to 130m long. This can be done while it is jacked up in 80m water depth.

INS to Boost Wind Turbine Installation Precision

Exail secured a contract to supply three Hydrins INS to Pliant Offshore. The units will be integrated into Pliant Offshore’s installation measurement system to improve the accuracy and efficiency of wind turbine installations. Pliant’s technology is designed to provide real-time measurements of the inclination and position of structures, such as monopiles, during installation. The system uses 3D point cloud technology combined with laser sensors to measure and virtually reconstruct objects with high accuracy.

The integration of Exail Hydrins INS enhances the system performance by providing precise positioning and motion compensation, even on moving vessels. This enables the installation measurement system to take continuous measurements during the pile-driving process, guaranteeing the correct positioning and stability of wind turbines in challenging offshore conditions.

MAN Engines Introduces New V12 Workboat Engine

MAN Engines has introduced its MAN D3872 LE432 workboat engine with a displacement of 30 liters.

The V12 engine has an output of 1,213kW (1,650hp) at 2,100rpm, making it suitable for medium-duty applications such as wind farm supply vessels, ferries, passenger ships and fishing boats. Further power variants of the MAN D3872 (1,471 and 1,618kW or 2,000 and 2,200hp at 2,300 rpm) for light applications have already started in production.

The MAN D3872 engine has a completely new basic engine and benefits from improved coolant delivery through a new coolant pump and thermostat housing, which contribute to the engine's high longevity. As an alternative, the engine is available with an outer skin cooling system instead of a closed cooling circuit. The distinctive cylinder head of the MAN D3872 has also been redesigned to optimize flow and cooling. In addition, the oil supply was adjusted by using flow-optimizing measures in addition to new oil pumps and new oil coolers.

The new common rail injection system is another important step for this next generation of engines: with an injection pressure of 2,200 bar, the basis is laid for achieving low fuel consumption and emissions. The new MD1+ engine control unit also achieves optimum engine tuning.

Another development goal was the high power density, so that the most powerful variant, the MAN D3872 LE433, has an output of 1,618 kW (2,200 hp) and a dry weight of only 2,720kg and a displacement of 54.7kW per liter.

Cummins Marine: Melding Future Fuel "Interest" with "Demand"

“We’re committed to diesel and we think diesel has a long runway” is how Cummins’ Eddie Brown discusses the challenge inherent in keeping existing engines in shape and running at peak efficiency while eying the development and delivery of new engines, including a new methanol-ready unit that the company had on display at SMM 2024 in Hamburg.

Kongsberg Digital Extends Digitalization Offering

Kongsberg Digital will integrate its Vessel Insight with the Smart Ship Hub platform to improve vessel and voyage performance, machinery condition monitoring, predictive diagnostics and overall health management. Smart Ship Hub, the Singapore-based company founded in 2021, is known for its expertise in using high-frequency vessel sensor data to deliver a comprehensive suite of machine learning-based services designed to benefit ship owners, operators, charterers and marine insurers by providing actionable insights and enhancing operational efficiency.

The collaboration will enable seamless data collection from connected sources and in-the-cloud and on-edge intelligence. By leveraging a dedicated customer cloud instance as well as edge access, the partnership promises a customizable experience in performance management, optimization, machinery condition and decarbonization, among other critical areas, both on individual vessel and fleet levels.

Danelec Simulation Tool for LNG Carriers

Danelec released a new simulation tool it says will bridge the gap between LNG carrier commercial and operations teams. LNG carrier operations are subject to several unique challenges, including balancing diverse factors to meet charter party requirements, meeting cargo temperature and pressure requirements at discharge, and optimizing voyage planning amidst variable weather conditions and route complexities to minimize consumption and maximize delivery.

By simulating expected vessel performance and providing optimized operational setpoints, the new platform enables operators to plan and execute voyages with greater efficiency. Detailed simulations encompass route waypoints, cargo composition, vessel loading, and forecasted weather, providing actionable insights to improve operations. Continuous mid-voyage updates enable operators to adjust to changing conditions in real-time, ensuring optimal reliquefaction and subcooling rates, engine modes, shaft speed, and GCU use.

Danelec says the suit can result in the potential to save more than 100 MT of LNG per voyage, with an estimated saving of $360k per vessel per year.

First Rim-Drive Thruster Achieves Silent-E Notation

Kongsberg Maritime’s rim-drive azimuth thruster has achieved Silent-E notation from DNV, the first of its kind to receive this certification. Installed on the new Commissioning Service Operation Vessel (CSOV) Norwind Hurricane and its sister vessels, the thruster demonstrated exceptional performance in reducing underwater noise pollution during a recent trial.

To assess the noise levels of the Norwind Hurricane, an extensive underwater noise study was conducted using hydrophones placed on the seabed. The results unequivocally confirmed the effectiveness of the rim-drive thruster in reducing underwater noise.

Roy Ove Standal, Chief Operating Officer at Norwind Offshore, said: “The rim-drive propulsion system stands out for its ability to reduce the need for additional support systems, leading to notable energy savings. It also contributes to increased onboard comfort due to its lower noise levels. Achieving the Silent-E notation further demonstrates our commitment to protecting the marine environment.”

“Swift by Name, Swift by Nature”

Zelim’s founder and CEO Sam Mayall has a simple mission: make man overboard recovery at sea easier, more efficient, more predictable. In fact, he wants to make MOB recover ‘boring’. To accomplish the job, Zelim debuted a comprehensive system, including the Guardian vessel and Swift in-water recovery system at SMM.

Ammonia Release Mitigation System

Azane Fuel Solutions received Approval in Principle (AiP) from DNV for its Ammonia Release Mitigation System (ARMS). The approval comes as Azane Fuel Solutions continue to develop technologies to safely handle ammonia as a fuel on board ships and builds on the company’s expertise within ammonia bunkering solutions. The Azane ARMS is connected to the vessel’s fuel and engine systems. It gathers the ammonia releases from these systems and ensures that any ammonia emissions from the ARMS to the surroundings stay below the required thresholds.

The aim is to protect the vessel’s crew and the environment from harmful concentrations of ammonia.

DNV’s approval adds to its prior approval in principle for the company’s floating bunkering terminal in 2022, and the world’s first safety permit for an ammonia bunkering granted earlier this spring.

Early, Rapid Detection of Cylinder Wear

Condition monitoring solutions company CM Technologies (CMT) developed new tools to assess the condition of lubricating oils and cylinder liners. The company’s new WBS IR Analyser is an all-in-one infrared-based solution designed to assess the Base Number, soot and water content of cylinder and system oils, while the new CMT Scuffing Sensor can detect sudden and severe wear of the engine’s cylinder liners and piston rings well before other systems can see it.

“Modern engines are less tolerant to the rigors of maritime operation than yesteryears’ workhorses and need to be correctly maintained and lubricated to prevent failure,” said Matthias Winkler, CMT’s Managing Director. “Engine technology has advanced markedly in recent years, but lube oil failure remains the most common cause of engine damage, accounting for 28% of all machinery insurance claims, with an average cost of $1.2million per claim. The condition monitoring technology we have developed can help optimize engine performance, prevent costly engine damage and downtime, and reduce insurance claims.”

Designed to measure three important parameters (water, BN, soot) instantly and simultaneously, the small, handheld analyzer incorporates the same infrared technology used for laboratory-grade oil screening to provide quick and reliable results onsite.

High-Pressure Ammonia Fuel Pump

Svanehøj has launched what it claims is the world’s first high-pressure centrifugal pump for ammonia fuel applications. The HP NH3 Fuel Pump delivers a fuel injection pressure of up to 100 BAR. It is based on the design of Svanehøj’s patented deepwell low-pressure fuel pump, a centrifugal low-pressure pump, which has sold more than 1,000 units since its introduction, with 100 of those units being used for ammonia. The new pump has a small footprint of 2,100x780x1,450 mm, making it a fit for the tank connection space in an ammonia fuel supply system.

The HP HP NH3 Fuel Pump is hermetically sealed with no mechanical shaft seals and designed with a magnetic coupling that ensures transmission of torque from the motor. The coupling containment shroud is made from magnesium-stabilized zirconium oxide, ensuring high temperature stability. For pumps installed in engine rooms or on deck, Svanehøj has added an optional fail-safe mechanism as a second barrier. In the unlikely event of a breach in the containment shroud, this mechanism will activate to contain the pumped media inside the coupling housing.

The pump is fully drainable and can be lifted out in one piece. It is designed with only one media-lubricated and easily changeable ceramic ball bearing for all axial loads. For the power transmission, Svanehøj has a heavy-duty drive with a carbon-reinforced and easily accessible timing belt system.

Iridium Unveils Iridium Certus GMDSS

At the opening of SMM 2024, Iridium unveiled its new Certus GMDSS, which features distress alert, safety voice and Maritime Safety Information (MSI), while integrating additional regulated services like Long Range Identification and Tracking (LRIT) and Ship Security Alert System (SSAS). Brian Hartin and Wooter Deknopper discussed the significance of the launch, as well as the ever evolving competitive landscape in the maritime satcom field, with Maritime Reporter TV.

Auramarine Launches Ammonia Fuel Supply System

Auramarine launched an ammonia fuel supply system designed in adherence to all safety, design and material requirements for the fuel. The system is suitable for both two-stroke and four-stroke engines as well as other ammonia consumers. Safety measures include gas and leak detection, ammonia capture, reliquefying and ammonia release mitigation functions. The system has been developed in collaboration with experts on ammonia as well as using findings from the HENNES research project which Auramarine participates in. Full and ongoing training in the safe use and operation of the system will be provided to all customers as part of Auramarine’s lifecycle services offering.

MAN Introduces New Four-Stroke Injection System

MAN Energy Solutions announced a new generation of its Common Rail injection system for its medium-speed, four-stroke engine portfolio. Its core components comprise an optimized and uniform high-pressure pump and a newly developed injector, integrating the CR 1.6 valve group and making the entire system setup more coherent. It is initially being introduced via the MAN 49/60DF engine.

MAN Energy Solutions reports that CR 2.2 can boast of up to 38% increased rail-pressure for all applications, and over 33% increased target time-between-overhaul intervals for most components. The CR 2.2 system features some 35% fewer high-pressure connections, meaning a significantly reduced risk of leakages and greater service-friendliness.

Other features of common-rail 2.2 include:

-

an increased system pressure up to 2,200 bar to comply with future emission limits while offering the best possible fuel consumption;

-

an electronically-controlled injector including an accumulator enabling the greatest flexibility with multiple injections and maximum stability during an injection event;

-

a reduced modular design for simplified service and allowing the maximum free space for engine maintenance.

Becker’s Wind-Assist Steering Technology

Becker Marine Systems introduced two new products which are designed to optimize vessel hydrodynamic performance: the Becker Daggerboard and the Becker Steering Gear.

The Becker Daggerboard is an anti-leeway fin designed for ships equipped with modern wind- assisted propulsion systems (WAPS). When using WAPS, the desired thrust ahead components drive the ship. Depending on the wind direction, there can also be stronger or weaker lateral force components leading to leeway from the desired course. Using a Daggerboard reduces these force components, requiring less compensation by the rudder. This increases efficiency and minimizes power consumption.

The Becker Steering Gear is equipped with a low-pressure hydraulic system, making it efficient, space-saving in design and suitable for small steering gear compartments, says Becker Marine Systems. There are eight types of Becker Steering Gear available, with torques ranging from 160 KNm to 500 KNm, designed for smaller vessels such as supply vessels, fishing boats, anchor-handling tug supply vessels and yachts.

In other news, the company will be delivering five Becker Full Spade Rudders with twisted leading edge, with each rudder having an area of 125m2, for VLCCs currently under construction at Qingdao Beihai shipyard for Euronav. These rudders are the largest that the company has provided for the maritime industry so far.