Tech Feature

Production Optimization

Retrofitting autonomous inflow control devices offshore China

Mojtaba Moradi, Jingheng Hau and Michael Konopczynski, Tendeka and Ling Dai et al, CNOOC China Ltd

Water breakthrough in a horizontal well is often the result of varying reservoir properties, layer pressure, and fluid contacts in zones intersected by the well. While inflow control devices (ICDs) can be used to mitigate and manage the reservoir fluid influx toward the wellbore, the technology is unable to adapt to the dynamic change in the reservoir if there is a high mobility contrast between the viscous oil and water. In addition, successful water production control with ICDs requires isolation in the annulus between the formation and the wellbore1&2.

During an intervention campaign in the Pearl River Mouth Basin of the South China Sea, CNOOC aimed to improve production by retrofitting a horizontal well located about 120km southeast of Hong Kong. Water mobility in the reservoir was at least 20 times higher than oil mobility and a strong aquifer was located below the well. The well was drilled along a heterogeneous formation with varying properties resulting in an uneven reservoir influx toward the wellbore. Although the well was already completed with passive ICDs, within a couple of weeks of starting production, the well suffered from severe early water breakthrough.

Global production optimization specialist, Tendeka, was contracted to perform an integrated study comprising history matching and performance evaluation of the existing completion. Sensitivity analyses were used to determine the best retrofit completion for the well using autonomous ICDs (AICDs) to ensure a balanced contribution from all reservoir sections. The bi-stable devices can control the reservoir fluid influx toward the wellbore while significantly limiting water production3-5.

Retrofit application

A well with a horizontal length of 536m was drilled in a thin formation with the oil column averaging 5m. In the initial production phase, 2,411 barrels of liquid were produced daily, including 1,885 barrels of oil with a water cut of 21.8%. After one week, the water cut exceeded 40%, and after one month reached 60% and decreased rapidly after that. The results of running PLT showed that the water rapidly broke through the high permeability zones, and the horizontal section was unevenly produced even with installed ICDs. As the crude oil viscosity of the producer well was 18.7cp, there was still residual oil around the well, and the remaining recoverable reserves was estimated to be 69,000m3, the implementation of AICDs was considered to improve the well performance.

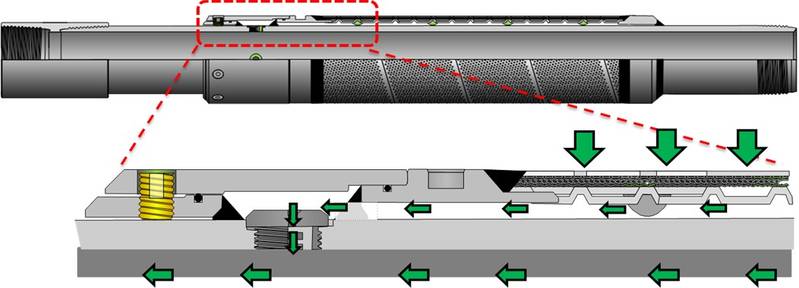

AICDs were introduced to function as standard ICDs prior to the breakthrough (proactive solution). It limits the production of unwanted effluents with lower viscosity after breakthrough such as gas in light oil and both gas and water in heavy oil production (reactive solution). It is a viscosity and density-dependent device which is typically incorporated as part of a screen joint as shown in Figure 1.

Figure 1: AICD unit mounted into sand screen joints illustrating production flow path.

For retrofit applications, an inner string consisting of AICD subs and swellable packers is installed within the existing wellbore. In this case, compartmentalization is driven by the existing wellbore, whether that be standalone screens or gravel-packed completion along with packers for zonal isolation, as shown in Figure 2, or with cased and perforated wells. If extra compartmentalization is required, chemical annular isolations can be used.

Figure 2: Retrofit AICD completion in existing standalone screen with the production flow path

Flow loop testing was performed to check AICD functionality where single-phase oil and water, and multiphase samples were flowed through the AICD to evaluate its performance. Under 500kPa differential pressure, the single-phase oil flow rate through the AICD is about 1m3/h, which is about 5.5 times higher than the flow rate of single-phase water. For multiphase oil-water mixtures under the same pressure difference, the higher the water cut in the oil-water mixture, the smaller the flow rate through the AICD. Several other tests with other fluids with viscosity ranges from 12 to 200cP have been reported.

It was possible for the well to install 3-1/2” AICD subs with swellable packers to retrofit the AICD completion. As shown in Figure 3, 54 AICD 7.5mm devices were retrofitted into the existing 5-1/2” ICD screen based on the results of a static wellbore modeling. If necessary, chemical packing material can be placed in the annulus at the original packer position to enhance the effective separation of the horizontal section.

Figure 3: The retrofitted AICD completion schematics

The optimum retrofit completion was to install a 2 3/8” inner string consisting of AICD subs and swellable packers inside the existing ICD/screen completion.

Optimized well performance

The well was successfully re-completed with FloSure AICD completions and over a nine-month period of production, well performance was optimized. ACID valves restricted liquid production from the first and fourth sections with high permeabilities, especially undesirable fluids, and greatly increased oil production in the second and third sections of well with low permeability, effectively controlling water production from the bottom aquifer.

In summary, the water cut was reduced from 97% to 87% helping produce 200% more oil compared to production prior to re-completion (Figure 4).

Figure 4: Well production profile (including prediction by simulation)

The performance simulation analysis shows optimum water control could be achieved by imposing effective back pressure against water production when the daily liquid production rate is around 11,000bbl/d. It is expected that the future liquid production rate will be maintained at 11,000bbl/d while the current water cut will be maintained with the AICD retrofit completion, compared to the existing ICD completion in which the water cut continues to increase.

Although the well was at a very late stage of its lifetime with an increasing trend of water cut (above 97%) and a significant volume of original liquid was already produced before operation, it is estimated that total oil production of 71,100Sm3 could be produced by the AICD completion. This is significant when noting that the well without AICDs could produce total oil volume of only 30,200Sm3 oil. In other words, an extra 40,900Sm3 cumulative oil production could be achieved by retrofitted AICDs completion extending well life for additional four years than previously anticipated.

The AICD completions effectively not only boosted oil production and saved the treatment cost of extra water production and chemicals but also allowed adding other low water cut wells to the production systems as extra capacities on the surface facilities became available. This successful application of AICD in this well has also opened up other similar opportunities that are currently being evaluated for the same application.

To date, more than 280 wells have been completed with FloSure AICD technology. With more than 50 of the wells completed successfully with AICDs in high oil viscosity environments, the technology has proven a robust solution to develop challenging reservoirs more efficiently. Retrofitting the existing completions with AICDs is now a common practice for some operators following successful installation in the pilot wells.

References

-

Dowlatabad, M. M. (2015, June 1). Novel Integrated Approach Simultaneously Optimising AFI Locations Plus Number and (A)ICD Sizes. Society of Petroleum Engineers. doi:10.2118/174309-MS

-

MoradiDowlatabad, M., Zarei, F., & Akbari, M. (2015, April 22). The Improvement of Production Profile While Managing Reservoir Uncertainties with Inflow Control Devices Completions. Society of Petroleum Engineers. doi:10.2118/173841-MS

-

Mohd Ismail, I., Che Sidik, N. A., Syarani Wahi, F., Tan, G. L., Tom, F., & Hillis, F. (2018, September 17). Increased Oil Production in Super Thin Oil Rim Using the Application of Autonomous Inflow Control Devices. Society of Petroleum Engineers. doi:10.2118/191590-MS

-

Moradi, M., Konopczynski, M., Mohd Ismail, I., & Oguche, I. (2018, December 10). Production Optimisation of Heavy Oil Wells Using Autonomous Inflow Control Devices. Society of Petroleum Engineers. doi:10.2118/193718-MS

-

MoradiDowlatabad, M., Muradov, K. M., & Davies, D. (2014, December 10). Novel Workflow to Optimise Annular Flow Isolation in Advanced Wells. International Petroleum Technology Conference. doi:10.2523/IPTC-17716-MS

Author details

Mojtaba Moradi

Mojtaba Moradi is a principal reservoir engineer at Tendeka in Aberdeen. He holds a PhD (2016) in petroleum engineering from Heriot-Watt University. He is a member of the European Association of Geoscientists and Engineers (EAGE), and SPE.

Michael Konopczynski

Michael Konopczynski is a director of subsurface engineering at Tendeka in Houston. He holds a BSc (1981) in mechanical engineering from the University of Toronto. He is a member of the Association of Professional Engineers and Geoscientists of Alberta (APEGA) and SPE.

Jingheng Hau

Jingheng Hau is Tendeka’s country manager, China. He joined Tendeka in 2015 and has worked in the oil and gas industry for nearly 20 years.