Tech Notes

New Products, Technologies and Systems

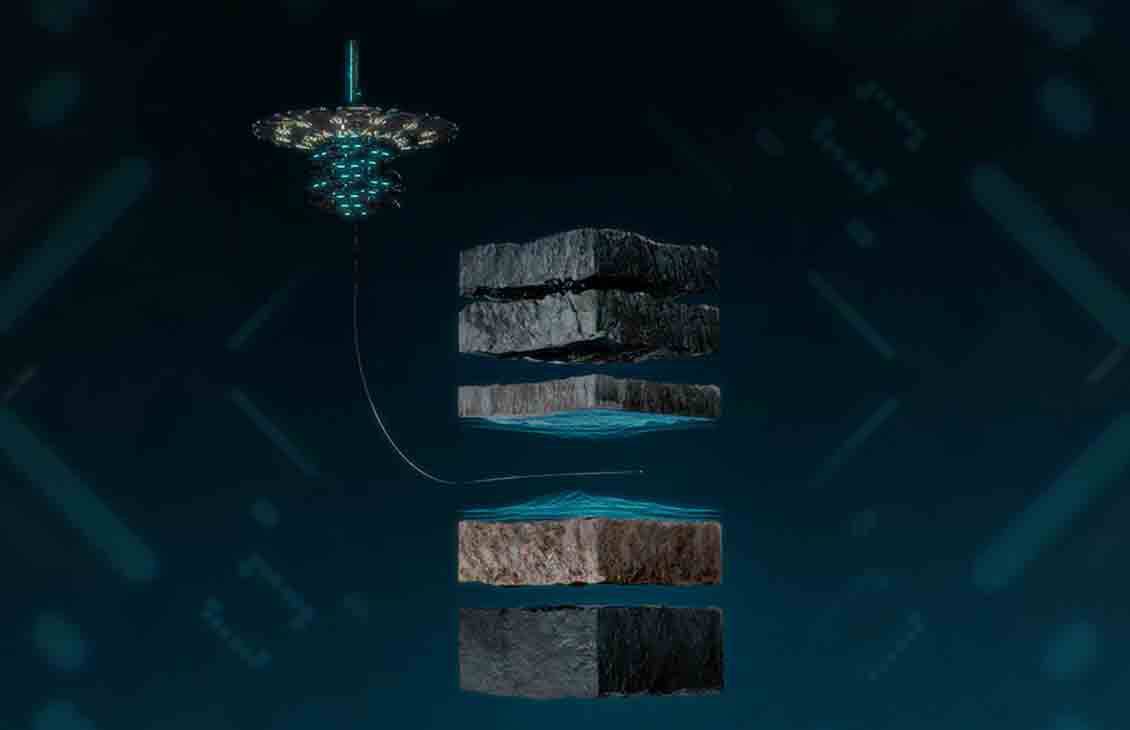

AI-Driven Geosteering Now Part of SLB’s Autonomous Drilling Solutions

SLB has introduced Neuro autonomous geosteering, which dynamically responds to subsurface complexities to drill more efficient, higher-performing wells, while reducing the carbon footprint of the drilling operations.

Using artificial intelligence (AI), Neuro geosteering integrates and interprets complex real-time subsurface information to autonomously guide the drill bit through the most productive layer or ‘sweet spot’ of the reservoir.

Intelligent closed-loop drilling system dynamically responds to subsurface geological information.

It identifies a well target, updates the well plan and trajectory, and communicates all the information to the directional driller, without any human intervention.

Neuro autonomous geosteering builds on the technology foundation of SLB’s Neuro autonomous directional drilling, which drills wells to a defined well target in accordance with the well plan, taking it a step further by incorporating high-fidelity downhole measurements that ensure certainty of well placement in the best part of the reservoir.

“Using advanced cloud and edge AI capabilities, the system automatically selects the best route for drilling the well based on high-fidelity downhole measurements, bringing the well trajectory in line with the real-world conditions of the reservoir.

“By drilling more consistent and higher-producing wells, our customers can optimize their field development plan while reducing operational emissions from drilling over the lifetime of the asset,” said Jesus Lamas, President, Well Construction, SLB.

NOV’s GustoMSC Unveils Quick Connector for Heavy Lift Cranes

NOV has introduced the Quick Connector, developed by its subsidiary GustoMSC, with the aim to optimize heavy lift operations across the offshore energy industry.

The Quick Connector, developed by GustoMSC, provides a secure and reliable connection between the crane’s lower block and the tools underneath, enhancing enhances the safety and efficiency of offshore lifting operations.

Intelligent closed-loop drilling system dynamically responds to subsurface geological information.

This is especially important for offshore wind sector as installing and maintaining offshore wind farms involves complex operations that require precise and secure lifting of various increasingly larger components, such as turbine blades, towers, and foundations.

The Quick Connector’s ability to swiftly connect and disconnect components minimizes downtime, reduces labor costs, and enhances overall project efficiency.

Most importantly, the remotely operated Quick Connector improves operational safety by eliminating the need for on-deck personnel to make the sling connection between the hook and tool during each tool change-out. Its integrated lower block design removes the need for rigging and enables a higher lifting height.

By integrating the pin with latches into the lower block, the tool connects seamlessly with the corresponding sockets, creating a secure and fail-safe lift.

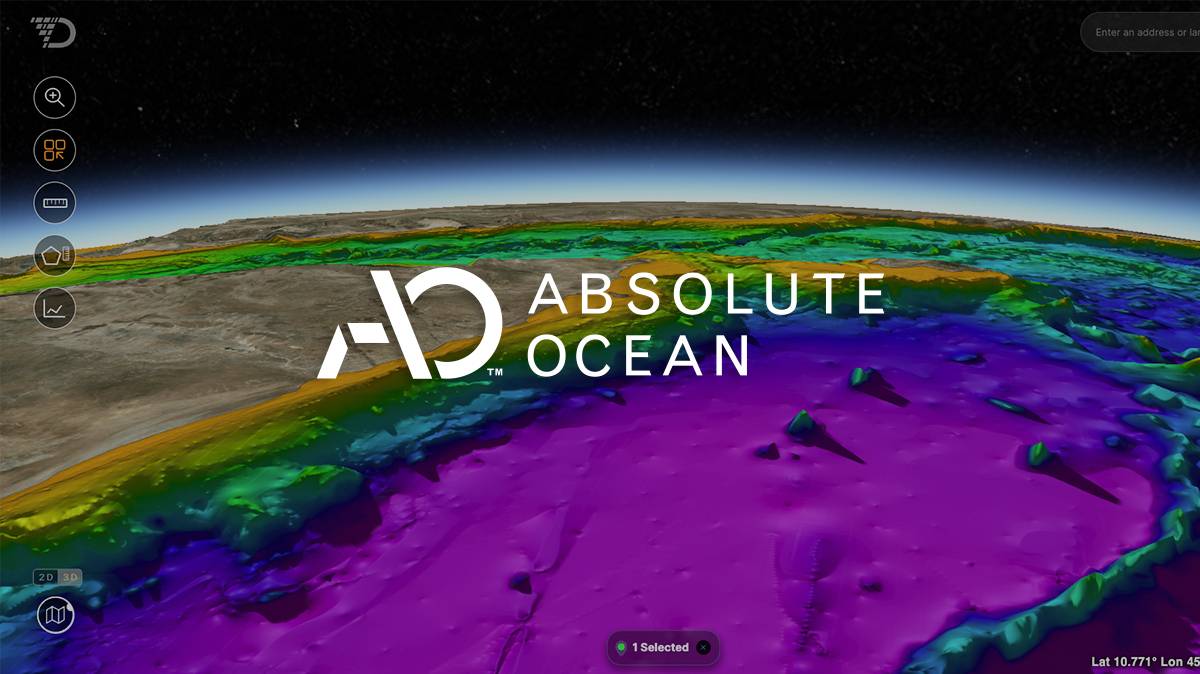

Terradepth Maps Out Cost-Efficient Ops for Offshore Energy Firms

Offshore energy developers can now access ocean mapping data in real-time from any location, cutting project development costs and increasing efficiency, by using Terradepth’s recently launched cloud-based tool Absolute Ocean.

Ocean data technology specialist Terradepth has launched a cloud-native geospatial platform for its offshore energy clients, dubbed Absolute Ocean.

Purpose-built to host complex maritime data, Absolute Ocean provides web-browser based access to ocean maps.

Subsea data collected for stakeholders can be shared, visualized and collaborated on in near real-time, empowering smarter decisions and ensuring sustainable growth in challenging marine environments.

The software operates in the cloud and can ingest diverse types of data, including bathymetric surveys, sonar scans, and video footage. By centralizing and simplifying subsea data access for teams, the secure platform offers visibility into the critical information needed for successful execution of projects.

“Current systems can take weeks to realize actionable data. Our offshore partners in petroleum and wind are enabled to access their data in near real-time from any location on our new platform. This leads to safer, more cost-effective, and more environmentally conscious operations,” said Joe Wolfel, CEO of Terradepth.

Tritek’s TRICON Dynamic Positioning System Gets New Interface

Tritek Power & Automation has unveiled a new graphical user interface for its TRICON DP during ADIPEC 2024 at ADNEC in Abu Dhabi.

The new interface is based on Tritek's experience in building automation systems for more than a decade and valuable input from shipowners and DP operators.

Tritek has been advancing the DP systems for vessel operations since 2022, after acquiring the rights to produce it from NAVIS. With plans in place for further improvement, the first and most important step was the upgrade of the obsolete DP user interface.

Working collaboratively with shipowners and highly experienced DP operators, Tritek has developed and enhanced the operator's control logic and interaction with human-machine interface. The new clear and intuitive interface is based on the OpenBridge 5.0 and provides the operators a positive experience for sustainable DP operations.

"Existing DP control systems were developed long ago, and their graphical user interfaces are not in line with current trends. Our aim is to gift the operators the best operating feelings. The Open Bridge solution best suits this due to its scalability, flexibility and holistic approach to the building of an intuitive user interface,” added Ralph Cabral, Managing Director at Tritek Power & Automation.

Beam’s AI-Driven AUV Set for 2025 Offshore Wind Debut

Beam, a company created by the recent merger of Rovco and Vaarst, has unveiled Scout, an autonomous underwater vehicle (AUV) driven by artificial intelligence (AI).

Scout, a concept expected to enter the market in 2025, will put the power of subsea inspection directly in the hands of wind farm operators.

This is an important step in Beam’s journey to develop cutting-edge underwater technologies that transform the viability and scalability of offshore wind.

The AUV will combine advanced AI, real-time 3D reconstructions, and precise navigation to deliver inspections that are quicker and more cost-effective.

As demonstrated in a world-first deployment at SSE’s Seagreen Wind Farm in September 2024, the system’s fully autonomous self-driving capabilities also require minimal human intervention.

Unlike traditional inspection methods that demand specialized vessels and expert crews, Scout is designed to be self-driving and will perform inspections by itself, reporting back at the end of the mission.

Beam intends for Scout to be deployed directly by people from existing Crew Transfer Vessels (CTVs) during routine visits.

This will enable a wider pool of people to confidently manage subsea maintenance of wind farms, helping to alleviate the pressing offshore wind skills gap that threatens the sector’s ability to scale.

Scout will enable 4K 3D reconstructions, such as year-on-year site comparisons, equipping teams with unprecedented insights into asset integrity and structural health. This will minimize the need for reactive repairs and reduce long-term operational costs, according to Beam.

Repsol, Baker Hughes to Advance Leucipa Automated Field Production Solution

Energy technology company Baker Hughes and oil and gas major Repsol have signed an agreement to collaboratively develop and deploy next-generation artificial intelligence (AI) Leucipa tool to optimize processes and workflows for oil and gas production.

Through this strategic collaboration, AI-powered automation workflows will be developed and implemented throughout Repsol’s assets around the globe to unlock new operational capabilities through the Leucipa automated field production solution.

The Leucipa automated field production solution helps oil and gas operators proactively manage production and reduce carbon emissions. Leucipa focuses first on the specific outcome an operator wants to achieve, harnessing and leveraging data to drive intelligent operations.

By automating production processes, Leucipa will reduce inefficiency, ensure more environmentally sound operations, and enable customers to help recover the millions of barrels that would have otherwise remained in the ground.

“Artificial intelligence is revolutionizing energy production, and Leucipa enables companies to operate more efficiently to recover more from their assets,” said Amerino Gatti, executive vice president of Oilfield Services and Equipment at Baker Hughes.

TAQA’s Inflow Control System for Optimized Reservoir Performance

Saudi Arabia-based oilfield services company TAQA has launched the M4 Inflow Control System, designed to help operators optimize reservoir performance while sustainably managing fluid production.

The M4 Inflow Control System dictates the flow of the undesired fluid (water and gas) and avoids any binary (open/close) effect that can result in instability, or worse, stop production.

According to TAQA, the system excels in controlling water in ultra-light and light applications and enhances gas production control, providing stability and flexibility in diverse reservoir conditions.

The M4 Inflow Control System technology incorporates an advanced pilot control system that is super sensitive to density, making it suitable for a wide range of oil types, including ultra-light, light, medium, and heavy oils.

It also features advanced multi-phase control, allowing the device to perform independently of its orientation in the wellbore.

“Its main benefit is precision control based on reservoir production. The device allows operators to maximize output without risking shutting wells in, so they can manage production continuously and efficiently, which translates into obvious financial benefits,” said Mojtaba Moradi, Subsurface Engineering Manager at TAQA.