Tech in Focus

Offshore Pipe Corrosion Protection

Offshore Pipe Corrosion Protection:

The RedLineIPS SmartPad System

The maritime and offshore sectors face unique challenges with Corrosion Under Pipe Supports (CUPS), which jeopardize the safety and longevity of critical infrastructure. The RedLineIPS SmartPad System, developed by Cogbill Construction is a patent-pending solution designed specifically for offshore and coastal facilities.

By Hani Almufti

The RedLineIPS SmartPad System includes SmartPads with Hydroseal Gasket, SmartBands with buckles, and the SmartTool, creating a comprehensive solution for external corrosion protection at pipe support points in offshore and coastal regions.

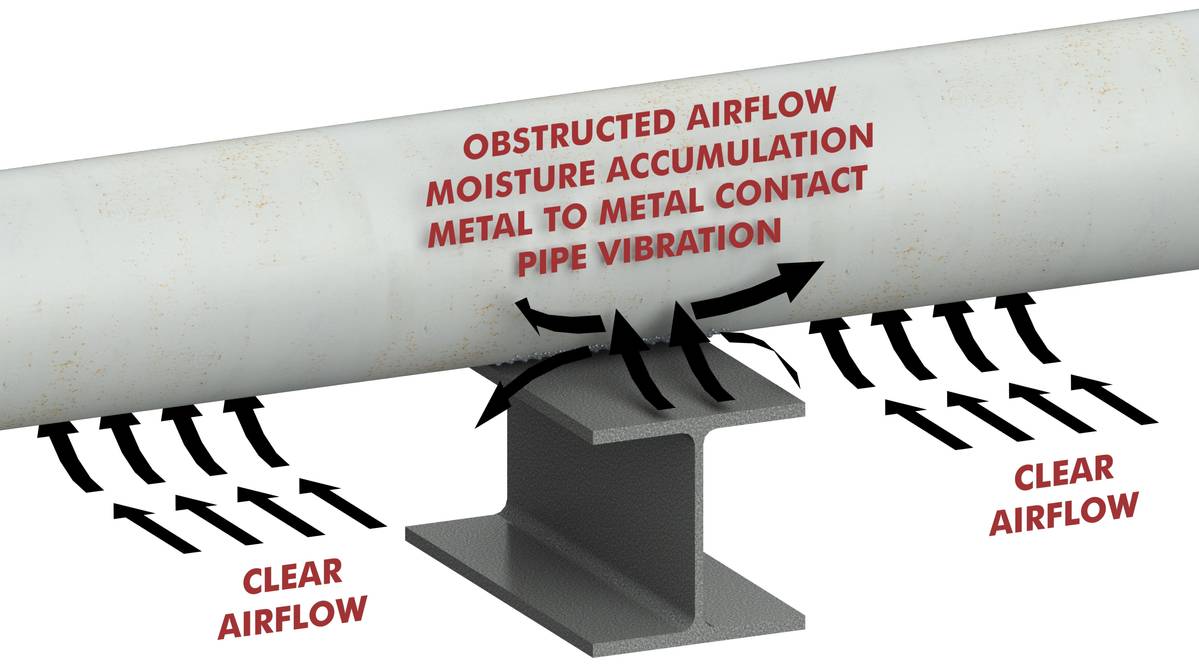

Image courtesy Cogbill ConstructionCUPS is particularly problematic in offshore and coastal environments, where exposure to salt-laden air, high humidity, and harsh weather accelerates corrosion. Pipes in these facilities are constantly exposed to a combination of mechanical stress, moisture retention, and galvanic corrosion. These factors can lead to catastrophic failures.

-

Mechanical Stress

In offshore platforms, movement from wave action, fluid flow, thermal expansion, and equipment vibration causes friction between pipes and their supports. Over time, this erodes protective coatings and exposes bare metal to corrosive elements.

-

Crevice Corrosion

Limited airflow in the tight crevices between pipes and supports traps moisture, particularly in humid and saline-rich offshore conditions. This promotes crevice corrosion, as the trapped water accelerates the degradation of coatings and pipe integrity.

-

Galvanic Corrosion

Metal-to-metal contact between pipes and supports creates an electrochemical reaction in the presence of moisture and salt, accelerating the corrosion of one metal while the other remains protected. This is a prevalent issue in offshore facilities where metal support systems are common.

The combination of these factors leads to chemical leaks, environmental hazards, costly repairs, and downtime—making effective CUPS prevention a critical requirement for offshore industries.

Built for Offshore Environments

The RedLineIPS SmartPad System was designed specifically to combat these challenges in maritime and offshore facilities. Unlike traditional solutions, the SmartPad System requires no welding or epoxy and offers rapid installation, removal, and reinstallation. Its components are built to withstand the harsh conditions of coastal and offshore environments, ensuring reliable performance for decades.

Key Features and Components

-

FRP SmartPad with Saddle Design

-

Material: Made from continuous-strand mat laminated with vinyl ester resin, providing exceptional durability and resistance to salt spray, UV radiation, and extreme temperatures (-60°F to 400°F).

-

Load Capacity: Independently tested to withstand over 111,300 lbs., making it suitable for heavy-duty offshore piping.

-

Saddle Shape: Evenly distributes weight, alleviating point-loading stress and protecting pipe coatings from friction and wear.

-

Recessed Grooves: Hold the SmartBands securely in place, preventing slippage during high-motion scenarios common in offshore applications.

-

-

Hydroseal Gasket

-

Material Options: Available in Silicone, PTFE, and EPDM to handle a wide range of chemicals and temperatures (-60°F to 570°F).

-

Functionality: Creates a NEMA-4-rated watertight seal, preventing moisture ingress and eliminating the conditions needed for crevice corrosion.

-

Performance: Conforms to uneven pipe surfaces, ensuring a reliable seal even on pipes with pre-existing damage from corrosion treatment.

-

-

SmartBands & Buckles

-

Material: Made from corrosion-resistant, continuous strand fiber-reinforced polymer with smooth inner surfaces to protect pipe coatings.

-

Retention: Capable of holding over 1,000 lbs. of axial force with a break strength exceeding 5,600 lbs., ensuring stability under the dynamic loads of offshore facilities.

-

Square Teeth Design: Maintains a tight fit for 20–23 years, preventing loosening due to vibration or thermal cycling.

-

-

SmartTool

-

Efficiency: Installs SmartBands in under two minutes, reducing labor costs and downtime during maintenance.

-

Ergonomic Design: Minimizes operator fatigue, making it ideal for repetitive tasks on offshore platforms.

-

Integrated Cutter: Ensures precise trimming of excess banding material for a clean, professional finish.

-

-

Optional PTFE Strips

-

Enhancement: Adds extra chemical resistance in extreme environments, such as exposure to hydrochloric or sulfuric acids.

-

Protection: Shields the Hydroseal gasket and SmartPad edges from aggressive corrosive agents.

-

How the SmartPad System Mitigates Offshore Corrosion

-

Prevents Galvanic Corrosion

The non-metallic FRP construction eliminates metal-to-metal contact, breaking the electrochemical circuit that causes galvanic corrosion in saltwater environments.

-

Eliminates Crevice Corrosion

The Hydroseal gasket blocks moisture from entering the pipe/pad interface, preventing the water pooling that fosters crevice corrosion.

-

Improves Airflow

The system’s quick removal and reinstallation enable rapid visual inspections, reducing reliance on costly methods like radiography or ultrasound. This improves the ability to detect early signs of corrosion and address them promptly.

-

Facilitates Proactive Maintenance

The system’s quick removal and reinstallation enable rapid visual inspections, reducing reliance on costly methods like radiography or ultrasound. This improves the ability to detect early signs of corrosion and address them promptly.

-

Reduces Mechanical Stress

The saddle shape evenly distributes pipe loads, eliminating point-loading stress that could otherwise lead to coating failure and localized corrosion.

Advantages for Offshore Applications

Compared to conventional solutions like welded metallic supports or epoxied FRP pads, the SmartPad System offers unique advantages tailored to offshore and coastal environments:

-

Corrosion Resistance: Built to withstand harsh marine environments with high salt exposure and humidity.

-

Installation Speed: Installs in under two minutes without welding, epoxy, or line shutdowns, drastically reducing downtime.

-

Versatility: Suitable for pipes from ½” to 72” in diameter, making it adaptable for diverse piping needs on offshore platforms.

-

Durability: UV-stable and long-lasting materials ensure reliable performance for 20–30 years, even in extreme conditions.

-

Cost Efficiency: Eliminates the need for expensive welding permits, skilled labor, and prolonged maintenance schedules.

-

Sustainability: Reusable components promote sustainability and reduce waste, aligning with green initiatives in maritime industries.

Applications in Offshore and Coastal Facilities

The RedLineIPS SmartPad System is purpose-built for the challenges of offshore and coastal facilities. Its robust design and advanced materials make it ideal for:

-

Offshore Platforms

Protects piping against the constant motion, high humidity, and salt spray found in offshore environments.

-

Coastal Refineries

Prevents corrosion in harsh chemical processing environments near the coast.

-

Maritime Pipelines

Ensures the integrity of above-ground pipelines exposed to fluctuating tidal conditions.

-

LNG Terminals

Handles extreme temperature ranges required for liquefied natural gas operations while preventing pipe damage and corrosion.

Early Adoption, Real-World Implementation

The RedLineIPS SmartPad System has already been adopted by industry leaders to enhance corrosion protection in challenging environments. Chevron has implemented the system on a newly built offshore platform, where its ability to withstand high humidity, salt spray, and dynamic loads ensures long-term reliability. Additionally, Formosa Plastics and Nutrien are deploying the SmartPad System at their coastal facilities in Texas and Louisiana. These plants face harsh environmental conditions typical of the Gulf Coast, and the SmartPad System's corrosion resistance, ease of installation, and cost-effectiveness have proven invaluable in mitigating maintenance challenges.

The , developed by Cogbill Construction, represents a major innovation in corrosion prevention technology for offshore and coastal facilities. Designed specifically for these environments, the system addresses the unique challenges posed by CUPS with unmatched durability, efficiency, and cost-effectiveness. By eliminating metal-to-metal contact, preventing moisture retention, and simplifying maintenance, the SmartPad System ensures the long-term safety and reliability of critical infrastructure.

With its proven success in offshore applications and adoption by major industry players, the SmartPad System is setting a new standard in pipe support technology for maritime and coastal industries. It is not just a product—it is a solution purpose-built to protect infrastructure in the most demanding environments.

About the Author

Hani Almufti, an engineer and senior manager at Cogbill Construction, focuses on piping supports and external pipe corrosion, with expertise in process improvement, and had published articles on related innovative solutions.