ROVs

Systems & Products

SMD’s ROV Trencher to Work in Japan’s Offshore Wind Farms

Toyo Construction has invested in Japan’s emerging offshore wind sector by purchasing a trenching remotely operated vehicle (ROV) from underwater technology and services company SMD.

The ROV will form part of Toyo’s expanding fleet of assets, with the business having also invested in a custom-built cable-lay vessel late in 2024.

The new SMD trencher will be used alongside the vessel to facilitate the safe and efficient burial of subsea cables.

SMD’s tailor-made trenching product range caters for a variety of different markets and end uses.

The self-propelled systems include the QTrencher (QT) and heavy tracked trencher ranges. QTrenchers are SMD’s fourth generation trenching ROV.

Subsea power available ranges from 400hp through to 2800hp all able to free fly with track upgrades. Heavy tracked trenchers are available in a range of chassis sizes and power ratings to suit trenching in hard ground up to 50MPa.

Trenchers can be configured to carry multiple tools, simultaneously or in interchangeable cartridges, including rock and clay chains, jetters, dredges, eductors and backfill tools to suit every soil combination.

“We chose to invest in this technology because of SMD’s prolific track recording in offshore wind, and of engineering excellence underwater globally. The team understood our unique requirements and adapted this vehicle into a bespoke product, suitable for our challenging operations,” said Tatsuyoshi Nakamura, COO at Toyo Construction.

Beam’s New 3D Mapping System

Beam, a company created by the merger of Rovco and Vaarst, has unveiled SubSLAM X3, a new subsea 3D mapping system which can be integrated to both work class and observation class remotely operated vehicles (ROVs).

SubSLAM X3 offers real-time, high-resolution 3D mapping, designed to enhance the monitoring and maintenance of offshore wind farms.

The system integrates artificial intelligence (AI), robotics, and advanced simultaneous localization and mapping (SLAM) technologies.

This integration is said to be critical for streamlining the development, construction, and maintenance phases of offshore wind projects.

The system provides 4K resolution video and precise 3D reconstructions, allowing for detailed inspection of underwater assets and intelligent autonomous control of underwater vehicles.

The newly designed SubSLAM X3 is more compact and lightweight than its previous version, making it suitable for integration into smaller observation-class ROVs as well as larger work-class ROVs.

Despite its reduced size, the system is capable of operating at depths up to 3000 meters and features enhanced sensor technology for improved image quality, especially in low-light conditions.

Kystdesign’s ROV Orderbook

Norwegian engineering firm Kystdesign has marked the successful start of 2025, having booked the largest order to date in the company’s history for its remotely operated vehicles (ROVs) and associated equipment.

In February 2025, Steading signed an agreement with an undisclosed client for the supply of four work class ROVs, including Constructor and Constructor Compact models, along with Launch and Recovery systems (LARS), Remote Operating Centres (ROC), additional spares and extra equipment.

The order is the largest to date in the company’s history, and is scheduled for delivery in the fourth quarter of 2025.

A month earlier, Kystdesign signed a contract with the Royal Netherlands Institute for Sea Research (NIOZ) for the construction of the advanced ROV, the Supporter 6000.

The Supporter 6000, designed for ultra-deepwater operations, will be delivered in June 2026 and will serve the entire Dutch marine research community.

The Constructor ROV is a powerful construction ROV uniquely designed to carry and operate large tools and modules

Kystdesingn’s Constructor ROV accommodates up to 41 electrical connectors for interface of external equipment, such as tooling, survey sensors and cameras, and all electrical power supplies are ground-fault monitored.

The ROV also features 24 hydraulic functions, all proportionally controlled. The ROV control system is prepared for a variety of auto functions like AutoPOS and AutoTRACK capabilities, in addition to over-the-horizon control from a Remote Operation Center (ROC) onshore.

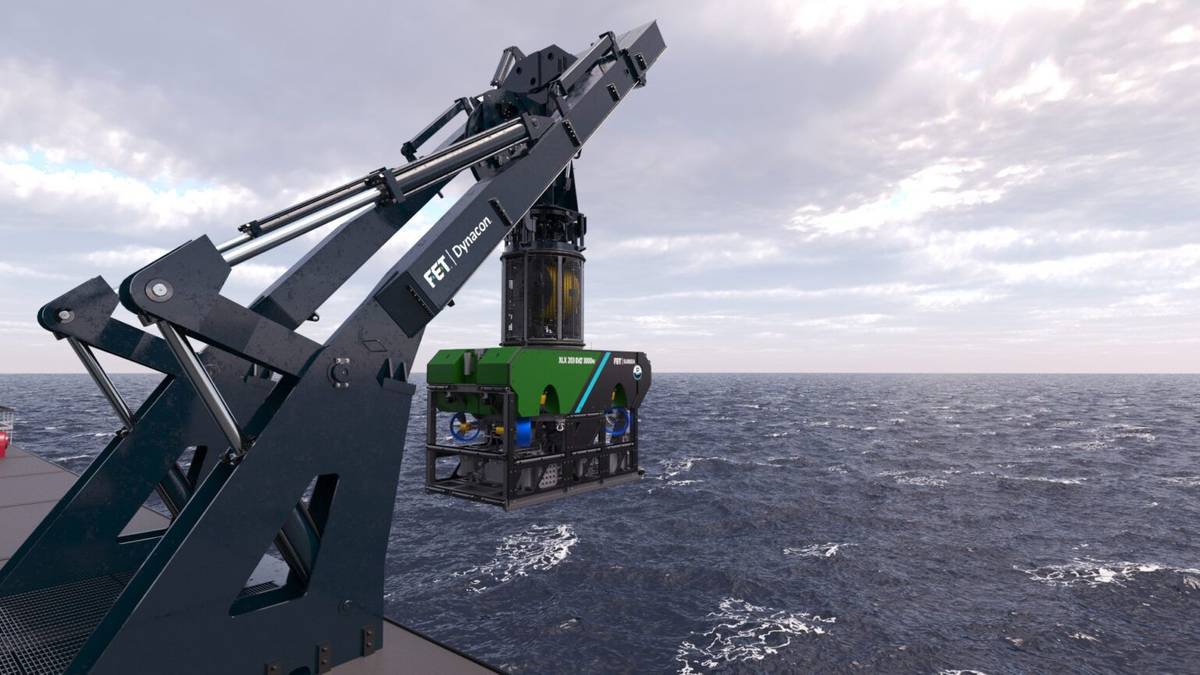

Spanish Subsea Services Firm Orders FET’s Latest Work Class ROV

Forum Energy Technology (FET) has secured a contract to provide a work class remotely operated vehicle (ROV) system and a Dynacon Launch and Recovery System (LARS) to Spanish-based subsea services provider ACSM.

FET’s XLX EVO II ROV system represents the latest evolution in the highly successful Perry XLX series and is equipped with the latest ICE Unity Control System, incorporating remote operations and machine learning.

It features significantly enhanced performance across the full range of demanding intervention and survey tasks without compromise to the outstanding reliability for which FET vehicles are renowned throughout the world.

Building on a long-term relationship, the FET Perry XLX EVO II will be delivered in the third quarter 2025 to support construction, drilling, pipeline and platform inspection, survey, salvage, cleaning and dredging.

“We are proud of the longstanding relationship we have with ACSM and look forward to continuing work with our peers in delivering cutting edge ROV operations in the energy sector.

“Our Perry XLX EVO II, coupled with the robust Dynacon LARS system, is built to provide innovative solutions to challenging subsea operations and is equipped to perform reliably in hostile environments around the world,” said Kevin Taylor, FET’s Vice President Operations – Subsea.

Tritech’s New Gemini Sonar

Subsea imaging technology provider Tritech International has launched a new dual frequency Gemini 1200id sonar, said to offer higher resolution imaging for work class remotely operated vehicles (ROVs).

The Gemini 1200id is built on the same robust platform as the industry standard Gemini 720is sonar. It features a wide 120° horizontal field of view when operating at both 720 kHz and 1200 kHz acoustic frequencies and offers improved attenuation of waterborne electrical noise for optimal imaging performance.

An integrated speed-of-sound sensor ensures that targets are displayed to a high degree of positional accuracy. CHIRP processing provides improved target separation over longer ranges, according to Tritech.

The 1200id is fully compatible with Tritech’s software package, Genesis. This ensures improved user interaction and allows for control of multiple Tritech products from within one software package. Software development kits (SDKs) are also available for Windows and Linux operating systems.

The Gemini 1200id employs a completely in-house developed analogue front-end solution that incorporates fully differential receiver channels for enhanced acoustic reception. Internal electronic circuits have been optimized and where necessary additional filtering exclusively employed to minimize self-generated noise.

These enhancements enable the Gemini 1200id to produce sonar images displaying sharp and bright acoustic returns on a noise reduced background resulting in crisp sonar images of impressive clarity.

“With its ultra-low-noise differential analogue front-end supporting a wide dynamic range optimized for sonar imaging applications, and with its ability to actively attenuate waterborne electrical noise from other subsea equipment, the Gemini 1200id provides work class ROV operators the clarity and confidence necessary for mission critical operations,” said Asim Azad, Hardware Engineering Manager.