Deepwater

Managed Pressure Drilling

Transforming Deepwater

Managed Pressure Drilling:

A Closer Look at the Subsea Integrated Riser Joints

By Nitin Kulkarni, Project Manager- MPD

Overview

Deepwater drilling has long been a cornerstone of global energy production, yet it remains one of the most technically challenging sectors of the oil and gas industry. The introduction of Managed Pressure Drilling (MPD) has significantly improved the safety and efficiency of deepwater drilling operations. One of the most critical advancements in this domain is the development of Integrated Riser Joints (IRJ), which serves as a fundamental component of MPD operations.

IRJ technology has been an important tool for developing deepwater MPD operations. A recent technical paper, published by the Society of Petroleum Engineers and presented at the IADC/SPE International Drilling Conference at Galveston, provides a detailed review of IRJ technology, covering its design, operational benefits, and implementation challenges. This article highlights the paper’s key points and examines the role of IRJs in deepwater MPD operations.

The Role of MPD in Deepwater Drilling

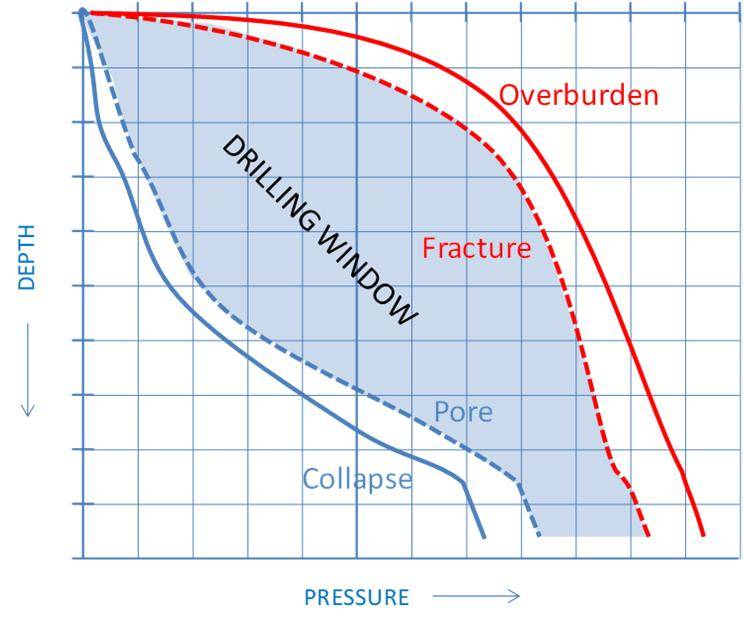

Managed Pressure Drilling (MPD) is an advanced technique designed to address the challenges associated with drilling in high-pressure, high-temperature (HPHT) reservoirs commonly found in deepwater environments. Conventional drilling techniques often prove insufficient when dealing with the narrow pressure margin between formation pore pressure and fracture gradients. This challenge is depicted in Figure 1. If the mud weight is too low, it may not provide sufficient hydrostatic pressure to counteract formation pore pressure, leading to influxes of formation fluids (kicks) and, in extreme cases, well blowouts. If the mud weight is too high, it may exceed the formation’s fracture gradient causing fractures and leading to lost circulation into the fractures.

MPD enables real-time pressure management while reducing the risk of influx and loss circulation and thus the technology has been instrumental in improving drilling efficiency, optimizing well designs, and enhancing safety measures in complex drilling environments.

The Evolution of Integrated Riser Joint (IRJ)

The IRJ is a crucial component in deepwater MPD operations, representing a significant advancement in MPD technology. It serves as an interface between the surface MPD system and the marine riser, enhancing operational efficiency and safety in deepwater drilling.

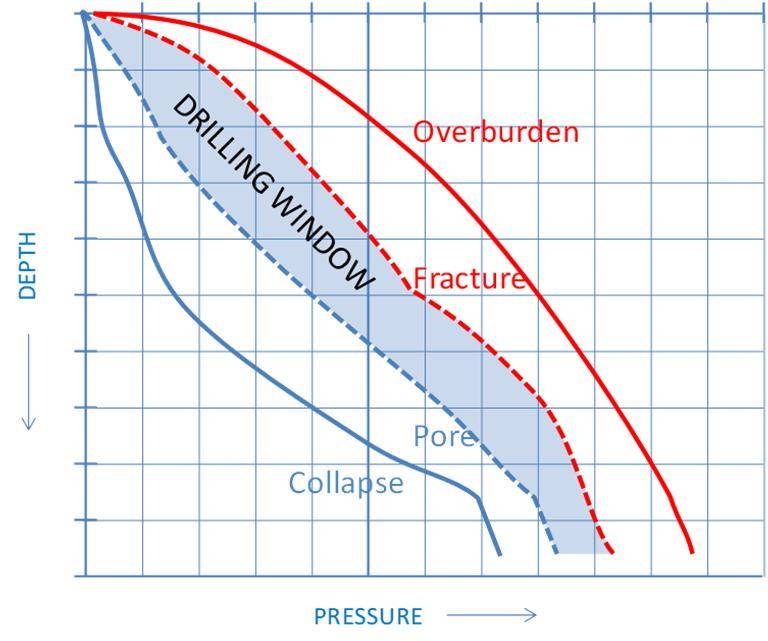

During the early days of deployment of MPD systems on floating rigs, several limitations impacted efficiency and safety of operations. One major challenge was the placement of the RCD designed for onshore and jack-up MPD systems, in deepwater environment. The RCD had to be installed above the tension ring on the riser as shown in Figure 2.

The RCD was mounted on a riser slip joint that remained collapsed and locked, restricting the movement and flexibility of riser operations in dynamic offshore environments.

RCDs originally designed for onshore applications did not have a top connection, preventing the installation of a diverter, a critical safety device in deepwater operations. Without the diverter feature, the system's capability to manage wellbore fluids and gas kicks in riser was significantly limited.

The integration of the RCD with the marine riser lead to the development of a new RCD design called the marine RCD. These RCDs were positioned above the tension ring (ATR-RCD) and they featured a larger inner diameter for accommodating the BOP test plug. Additionally, the inclusion of a top flange allowed for the installation of a conduit connecting the RCD to the rig's diverter, improving safety and reducing environmental risks.

The installation above the tension ring required modifications to the marine riser setup, leading to increased rig-up time and complexity. This presented several challenges and affected the efficiency and flexibility of deepwater MPD operations. One of the most significant drawbacks was the space limitation. Since the ATR- RCD was positioned above the tension ring, it occupied considerable space, thereby reducing the available room for the rig’s telescopic joint.

The development of the Below-Tension-Ring RCD (BTR-RCD) and the IRJ system effectively addressed these limitations by seamlessly integrating the system directly into the marine riser.

Components and Functions of the Integrated Riser Joint System

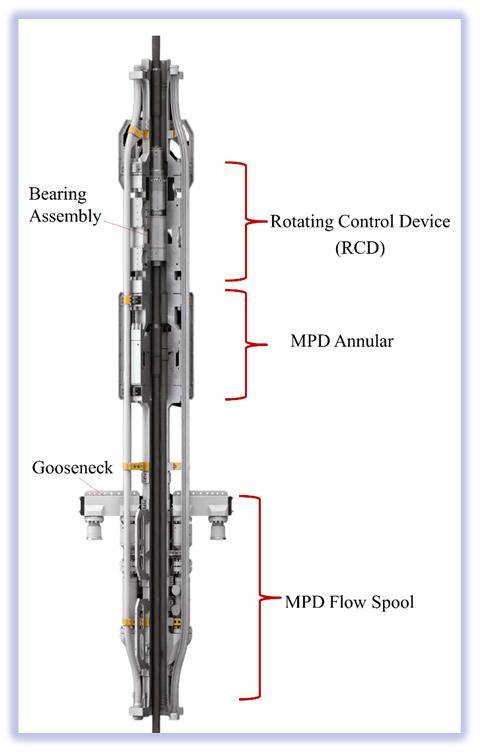

The IRJ consists of the following key components highlighted in Figure 3:

Below-Tension-Ring Rotating Control Device (BTR-RCD)

The BTR-RCD is an essential component of the IRJ system. Similar in functionality of onshore RCD, the BTR-RCD diverts returning fluids away from the rig floor while creating a sealed environment around the drill string and allowing the vertical and rotational movement of drill pipe essential for drilling operations. The primary benefits include:

-

Continuous pipe movement under pressure.

-

Prevention of uncontrolled release of gas.

-

Reduce the risk of stuck pipe and wellbore instability.

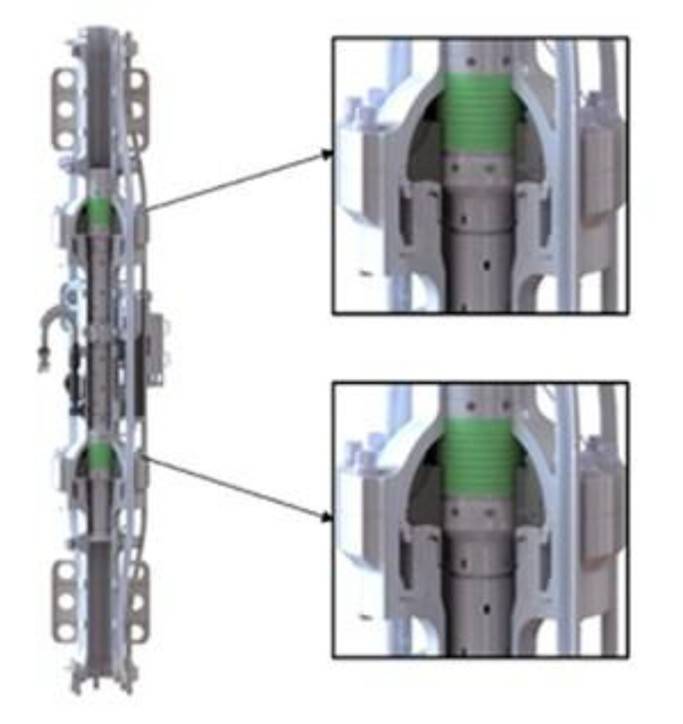

Active Control Device (ACD)

An alternative to the BTR-RCD is the Active Control Device. Unlike the RCD, the ACD does not require rotation and uses a pressure-activated sealing system. The ACD can maintain wellbore integrity even under high-pressure conditions and is particularly useful for deepwater MPD operations.

MPD Annular and Flow Spool

The MPD Annular, also called Annular Isolation Device (AID), acts as a barrier for isolation of the wellbore below the RCD when the RCD or ACD needs servicing. It provides additional pressure control, ensuring continuous wellbore integrity.

The Flow Spool is part of the of IRJ that facilitates the circulation of drilling fluids from the annulus to surface equipment. It is designed with gooseneck connections and high-pressure hydraulic valves, which play a crucial role in controlling fluid returns and ensuring pressure control throughout the MPD system. The goosenecks provide flexible hose connections, allowing for smooth flow transitions and minimizing pressure drops. The flow spool's hydraulic valves allow operators to dynamically adjust flow paths, enabling precise choke management, influx control, and pressure balancing. Additionally, integrated pressure and temperature sensors within the flow spool continuously monitor real-time well conditions, providing critical data for early detection of abnormal wellbore events.

These advancements have allowed safer and more efficient deepwater drilling operations, minimizing downtime and improving well control capabilities.

In addition to the main components of IRJ, several auxiliary components are required for the functioning of IRJ.

Choke, Kill, and Boost Line Conduits: The IRJ integrates choke, kill, and boost line conduits with the marine riser, ensuring seamless alignment, pressure integrity, and compatibility with the deepwater well control systems

Integrated Umbilical System

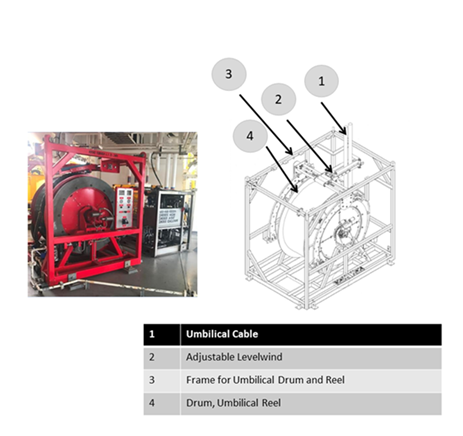

The umbilical cable serves as a multi-functional conduit, facilitating the operation of various subsea components by transmitting hydraulic power, electrical signals, and data communication between the surface control unit and subsea IRJ components. An example is shown in Figure 5.

The installation process begins with deploying the umbilical reeler, which ensures controlled spooling and unspooling of the umbilical cable. Once the umbilical is positioned, hydraulic and electrical lines are connected between the surface control unit and the subsea Interface connection point of the IRJ. To verify system integrity, comprehensive testing is conducted to confirm the data and signal transmission and power supply, ensuring proper communication with the surface control system.

The electro-hydraulic control system is essential for centralized management of the IRJ functioning providing, hydraulic, electric power and real-time control of the critical functions of IRJ.

Advantages of IRJ Technology in Deepwater MPD

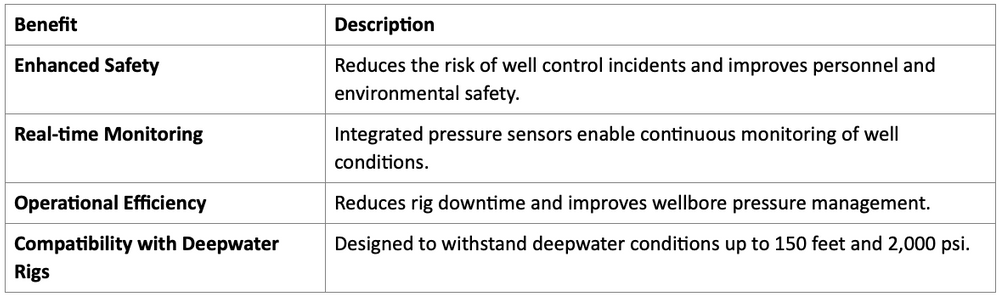

The implementation of IRJs in MPD operations offers several advantages, as outlined in the paper:

Technical Challenges and Maintenance Considerations

Despite their advantages, IRJs pose several technical and operational challenges The highly integrated system that combines fluid circulation, hydraulic controls, and electrical cables within a single unit. Its maintenance and repair require expertise across multiple disciplines, including mechanical, hydraulic, electrical, and control systems.

Their deployment in a subsea environment subjects them to extreme conditions, requiring robust maintenance strategies to ensure reliability. Some key challenges include:

-

Water Ingress and Corrosion: Continuous exposure to seawater increases the risk of equipment degradation.

-

Complex Maintenance Procedures: Retrieving and replacing IRJ components requires extensive rig downtime and specialized personnel.

-

Integration with Existing Rig Infrastructure: Ensuring seamless communication between the IRJ and the surface control system demands meticulous planning and execution.

To mitigate these challenges, proactive maintenance programs, routine inspections, and collaboration with original equipment manufacturers are essential.

Future of IRJ Technology in Deepwater Operations

As deepwater exploration continues to push technological boundaries, the role of IRJs in MPD operations will only expand. Innovations in automation, digitalization, and remote monitoring are expected to enhance IRJ capabilities, making deepwater drilling even safer and more efficient. Additionally, the integration of Artificial Intelligence (AI) and machine learning algorithms could further optimize wellbore pressure control, reducing reliance on manual interventions.

MPD Engineers remain active in driving these advancements. His expertise and contributions to the field continue to shape the future of deepwater MPD, ensuring that offshore drilling operations evolve in alignment with modern safety and efficiency standards.

Conclusion

The Integrated Riser Joint (IRJ) has emerged as a cornerstone of deepwater MPD, offering significant improvements in well control, operational efficiency, and safety. As highlighted in the paper, IRJ technology represents a paradigm shift in deepwater drilling, enabling more precise pressure management and reducing operational risks.

About the Author

Nitin Kulkarni is a MPD specialist with 20 years of experience in drilling engineering, operations, and technology development. Currently working with Blade Energy Partners in Houston Texas, he leads deepwater MPD and well-control projects, integrating advanced drilling technologies to enhance safety and efficiency. His expertise spans both operators and service providers, giving him a deep understanding of the drilling value chain. Nitin is also dedicated to training industry professionals on MPD best practices.

About the Paper

The paper, "Review of Design and Operation of the Integrated Riser Joints Used in Deepwater MPD Operations," was presented at the IADC/SPE International Drilling Conference and Exhibition 2024 in Galveston, Texas, USA. It explores the role of Integrated Riser Joints (IRJs) in Deepwater MPD systems and discusses design considerations, operational challenges, and field applications, highlighting how IRJs enhance safety, efficiency, and well control in deepwater drilling.