Meet the CTO: David Shea, Kraken Robotics

“Innovate or Die” is the Kraken Robotics’ Way

Since its founding in 2012, Kraken Robotics has operated by the succinct motto: “Innovate or Die.” Fast forward to 2024, and it is a global powerhouse, publicly traded with 250 employees and revenues fast approaching the $100m mark. David Shea has been with the company since the start and today serves as its Chief Technology Officer. He discusses the technologies and trends that will power his company’s growth into the future.

By Greg Trauthwein

Watch the full, uncut video interview with David Shea on Marine Technology TV:

Dave, to starts us off can you give a ‘by the numbers’ look at Kraken today?

Kraken is a relatively young company, starting the business in 2012, and headquartered in St. John's, Newfoundland & Labrador. Back then we only had six employees: myself, our founder Karl Kenny, and a handful of other folks. Since then we've grown, and today we're about 250 people worldwide. We have offices in Nova Scotia, Scotland, Germany, Brazil, Denmark, and in the U.S. We are publicly traded, and our 2023 revenues were about 70 million, reflecting an approximate 70% growth over 2022. We're anticipating being somewhere between 90 and 100 million in 2024.

What about the tech development in that 12-year span?

In the beginning, we were building sonar systems, putting those sonar systems onto other people's underwater vehicles. Since then, we moved up market into building other components for underwater vehicles. For example, we have pressure tolerant batteries now, coming out of our facilities in Germany.

We have underwater laser scanners, we have launch and recovery systems, and as we started delivering complete solutions. Mine hunting and mine countermeasures are our bread and butter, and we deliver a complete mine hunting solution for NATO navies around the world.

We have moved, too, beyond delivering products, now also delivering services. We’ve been running a robotics as a service (RaaS) business for the past few years, which helps to support the commercial business. Take for example offshore wind, where they may not be looking to acquire a bunch of equipment, and they may not be looking to manage the life cycle of that equipment. They simply have a job that needs to be done – a pipeline to be surveyed or a cable route where they need data. We can go in, get and deliver the data, and get out.

What are the prevailing trends and technologies that you see today driving your business in the future?

Continued improvement on size, weight and power (SWAP) is one of the big drivers across the industry, and it's been that way for a long time. We're seeing underwater vehicles both getting much bigger in terms of XL vehicle programs, which require more batteries and more power. We also see vehicles getting much smaller, lower cost platforms.

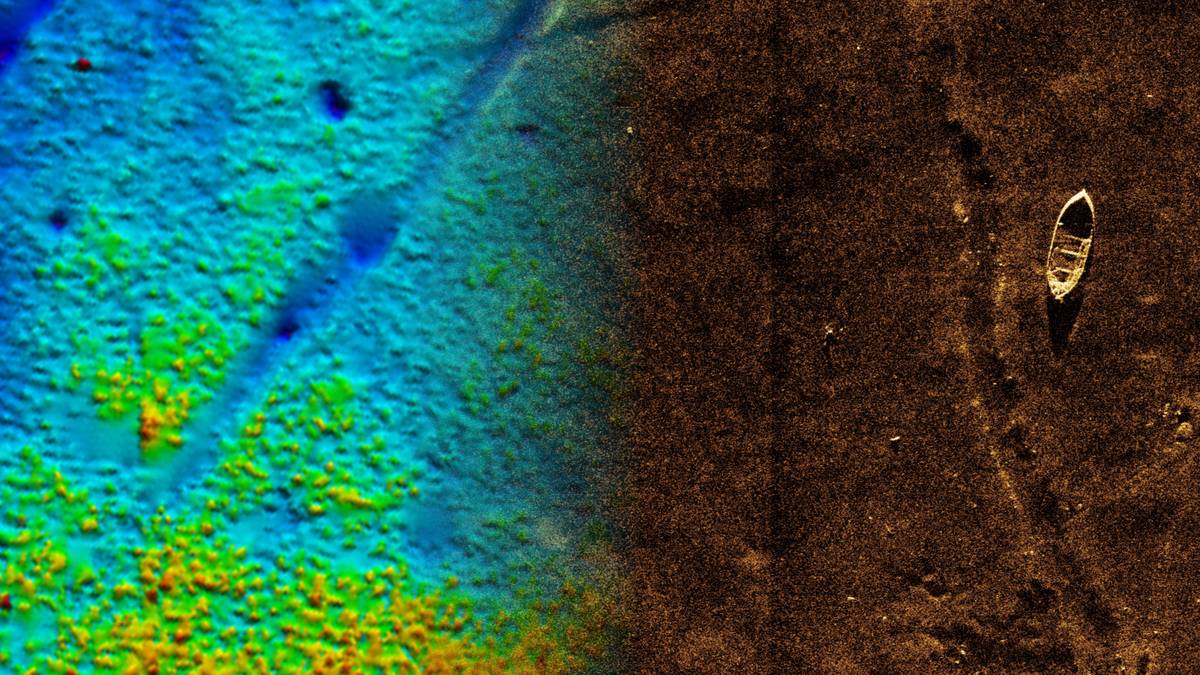

On the sensing side the synthetic aperture sonar is our core technology, focused on higher quality, higher resolution, longer ranges, but also on achieving a lower cost.

Our target has always been to compete against existing legacy technologies and educating customers about the benefits of the technology, showing them that synthetic aperture is not just reserved for very expensive, exotic military applications. It's an affordable tool to give you a higher area of coverage at a lower cost.

And of course, there’s artificial intelligence (AI). Not just getting better data, not just getting more data, not just running systems for longer, but what do you do with all that data? How do you process it? How do you perceive it? Things like automated target recognition, being able to comb through a large volume of data and automatically pick out objects of interest, but also improving quality control, automated quality metrics, allowing the robots themselves that we put in the water to make decisions.

Can you discuss one recent or ongoing project that you believe highlights the capabilities of Kraken Robotics?

We wrapped up a survey for a defense customer in Australia, where we were using our technology, our vehicles, and our personnel, operating those systems as a service; not to replace what that defense customer was doing, but to augment those capabilities. We were doing port and harbor security, doing route survey, using this technology to provide critical information in a timely manner, and showing them that you don't have to go through a long complicated acquisition process and train up all your sailors.

The customer actually owns some of our technology already, but that technology was deployed in another mission and they asked for help. We operated for about six months around the clock, nonstop collecting data, and passing that off to the customer on regular intervals. Once the job was done, we packed up all our kit, shipped it back up to our main facility in Canada, where we clean and polish it, and get it ready for the next mission.

When you look at the region where you live and work – the Newfoundland & Labrador Cluster – what do you count as the leading benefits?

One of the things that everybody talks about when they travel to Newfoundland and Labrador, and when they travel to the east coast of Canada, is the people. The connections that people build, the relationships that they have. They talk about how friendly the locals are, how warm and welcoming they are, that sense of community. From a technology perspective and a tech industry perspective, we have a similar value. It's truly the people behind the companies, the people behind the technologies, the people behind the products, and that capacity for collaboration that we have, especially on the East coast where we have one of the harshest environments in the world, being the Atlantic Ocean.

Canada is a country surrounded by three oceans. We have the longest coastline in the world, and yet we have this concentration of technology happening out here on this rock in the middle of the North Atlantic. Part of that is because the people are resilient and innovative, willing to try and solve some of these difficult problems. Partly it’s because we have this fantastic testing environment where if you can make something work in the North Atlantic off of Newfoundland, you can make it work anywhere.