Transforming Offshore Surveys with Advanced Imaging and Real-Time Data

Technicians prepare an ROV equipped with a Rayfin Camera for an inspection.

Credit: SubC ImagingThe demand for more precise, efficient, and safer operations has never been higher in offshore operations. For 15 years, SubC Imaging, headquartered in Clarenville, Newfoundland & Labrador, has been at the forefront of this transformation, providing cutting-edge technologies that address the critical challenges survey and inspection teams worldwide face. With a deep commitment to solving customer pain points, SubC Imaging has consistently developed innovative solutions that enhance data integration, streamline operations, and drive the offshore industry toward a digital future.

Customer-Centric Innovation

SubC Imaging’s philosophy has always been grounded in understanding and addressing the needs of its customers. This approach has proven key in the offshore energy sector, where the stakes are high and operations are complex. Survey and inspection teams often face challenges that demand more than advanced technology; they require solutions tailored to their needs.

This commitment to customer-centric innovation is evident in SubC Imaging's product development process. By actively engaging with clients and understanding their pain points, the company has developed technologies that meet and exceed industry demands. One of the most significant trends observed in recent years is the growing need for better data integration. As companies increasingly adopt digital tools to manage their offshore assets, the ability to seamlessly integrate data from various sources has become essential.

Meeting the Demand for High-Quality, Integrated Data

The ability to gather, process, and analyze data quickly and accurately in offshore operations is paramount. SubC Imaging has recognized this need, particularly as the industry shifts towards offshore digitalization, digital twinning, and other advanced techniques. This shift is crucial for monitoring the condition of offshore structures, predicting maintenance needs, and optimizing operations. However, their effectiveness relies heavily on the quality and integration of data.

SubC Imaging has recognized this need and responded with solutions designed to ensure that data from its systems can be easily integrated into broader digital frameworks. The company’s advancements in this area are not just about capturing high-quality images and videos; they’re about ensuring this data is readily accessible and usable. Offshore operators can make informed decisions more quickly, whether they’re assessing the condition of a subsea structure or planning a complex inspection.

Breakthrough Solutions: Rayfin Single-Channel Inspection and Rayfin Rapid Digital Imaging

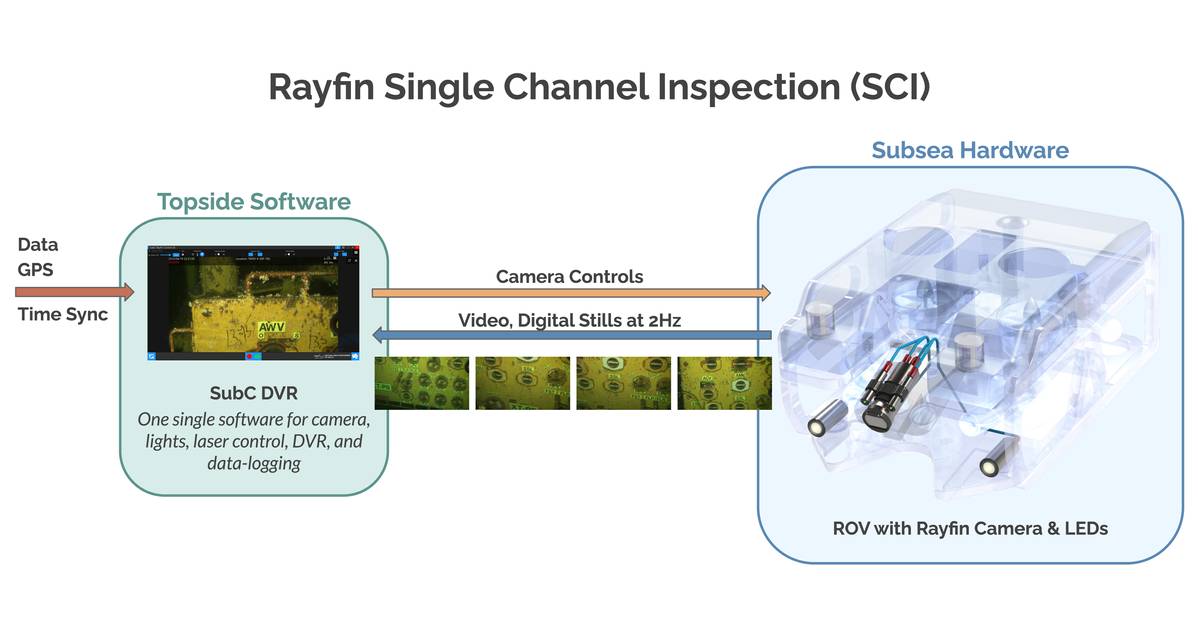

One of the standout examples of SubC Imaging’s customer-focused innovation is the Rayfin Single Channel Inspection (SCI) software. Developed in direct response to customer feedback, Rayfin SCI is designed to reduce the time and effort required to process survey data. The software integrates seamlessly with SubC’s cameras, lights, and lasers, offering a powerful tool that enhances the efficiency of survey operations.

Rayfin SCI has quickly become a game-changer for companies involved in offshore surveys. Ocean Ecology, a leading survey company, has praised the software for its impact on their operations. “The Rayfin SCI software from SubC Imaging has been a game-changer for OceanEcology's teams, cutting our post-survey processing times by at least half, and even more for larger projects. The efficiency it offers is unparalleled, making it an invaluable tool for our survey operations”, said Ashley Kirby, Head of Survey at the company.

Another stand out of SubC’s recent technology developments is Rayfin Rapid Digital Imaging. Rayfin RDI captures thousands of ultra-clear still images of subsea structures at more than double the speed of conventional ROV video inspections. These digital images deliver superior resolution and zoom capabilities compared to traditional video frames. Inspection teams can review the images offline while the ROV continues with other tasks, significantly cutting down on vessel time and operational costs. The high-resolution imagery can be leveraged to generate detailed 3D models, providing a comprehensive view of the structure.

Wood, a globally renowned leader in project management, engineering, consulting, and technical services for energy and materials markets, has been using SubC’s RDI as a simple and cost-effective inspection approach with greater efficiency than the inspection methods they used in the past. “The level of detail captured by RDI has exceeded our expectations. It has enabled us to conduct the inspection of subsea assets more efficiently and cost-effectively than with traditional methods”, noted Clinton Jensen, Field Engineering & Inspection Team Lead, Wood.

These testimonials underscore the real-world benefits that SubC Imaging’s technology delivers. By drastically reducing inspection and processing times while delivering the highest quality data, Rayfin SCI and RDI technologies are enhancing operational efficiency and contributing to more accurate and timely decision-making—an essential factor in the offshore industry.

Driving Offshore Digitization

SubC Imaging’s commitment to innovation extends beyond individual products. The company is deeply involved in the broader trend of offshore digitization, which aims to enhance efficiency, safety, and environmental sustainability. Offshore digitization involves the use of digital technologies to collect, process, and analyze data from offshore operations, enabling companies to make better decisions and improve overall performance.

One of the key areas where SubC Imaging is making a significant impact is in real-time data capture and integration. The company’s DVR systems, when paired with Rayfin cameras, allow for real-time video streaming and data recording. This capability is particularly valuable in hazardous environments, where it’s often impractical or unsafe to have personnel on-site. By enabling remote monitoring and assessment, SubC Imaging’s solutions help to reduce risk and improve safety.

The data collected by SubC’s systems can be easily integrated into larger digital frameworks, supporting a range of applications from predictive maintenance to environmental monitoring. This integration is essential for companies looking to stay ahead in a competitive and increasingly regulated industry. The ability to monitor offshore assets in real-time and predict potential issues before they become critical can lead to significant cost savings and operational efficiencies.

Shaping the Future of Offshore Technology

As the offshore energy sector continues to embrace digitalization, the role of companies like SubC Imaging will only become more critical. By focusing on solving customer problems and staying ahead of technological trends, SubC Imaging is not just a provider but a partner in the industry’s evolution. The company’s ongoing commitment to innovation ensures that its clients are equipped with the tools they need to succeed in an increasingly complex and competitive environment.

Where efficiency and safety are key, SubC Imaging stands out as a leader in delivering integrated, high-quality data solutions. With its roots in the Newfoundland and Labrador technology cluster, SubC Imaging is helping to shape the future of offshore operations, one innovation at a time.